flowplus

Sensors and process monitoring for absolute process reliability

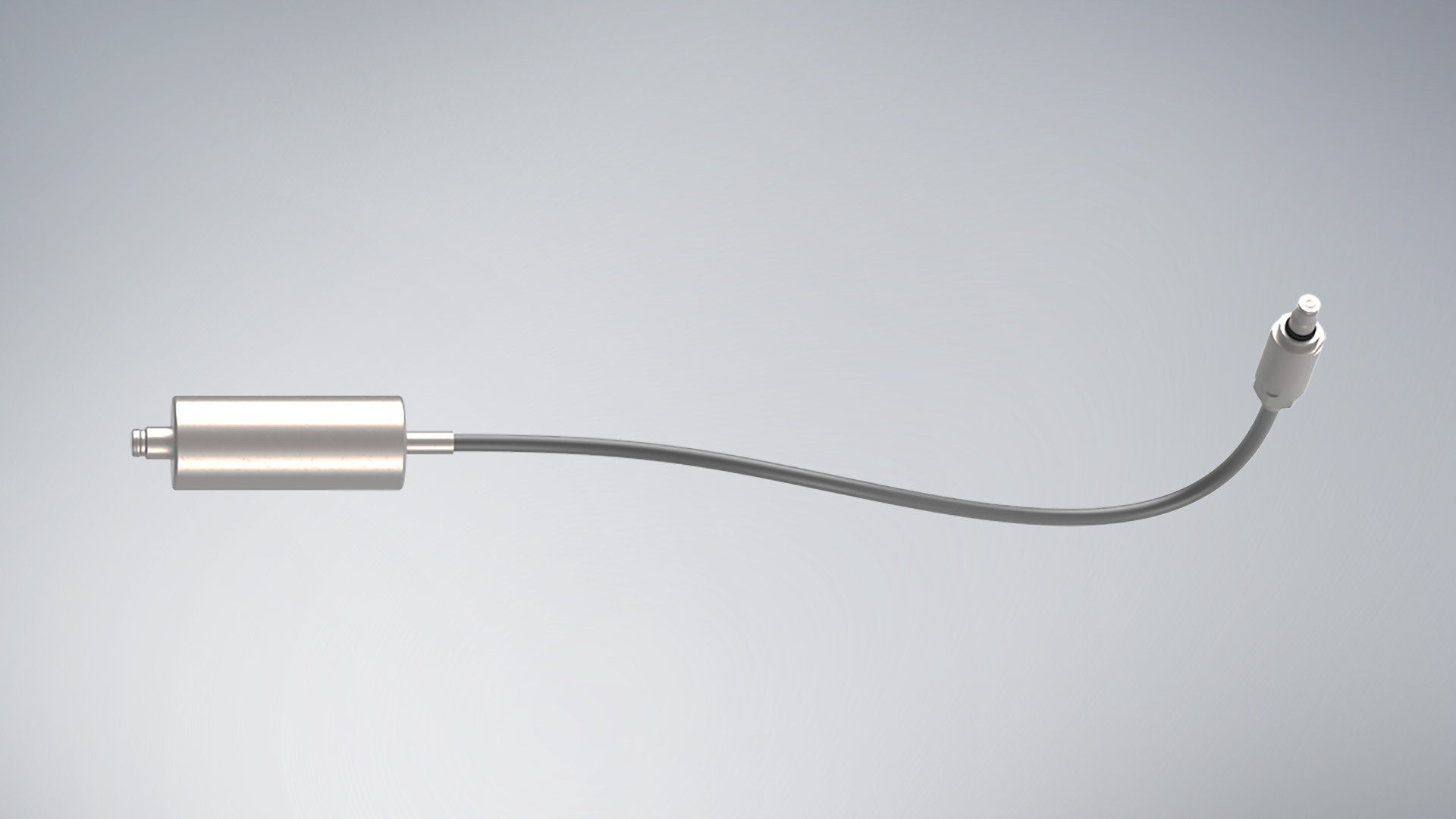

flowplus-SPT M6 J

With the flowplus-SPT M6 J, ViscoTec is launching a flush-mounted pressure sensor with a largely chemically resistant stainless steel pressure diaphragm. The pressure transducer of the miniature sensor is screwed into the process connection with a fine thread (M6 x 0.75) and realizes both pressure and temperature measurement in one periphery.

The flowplus-SPT M6 J sensor is available in two versions, which differ only in the output measuring signal. The voltage version provides a measuring signal of 0-10V and the current version a measuring signal of 4…20mA.

Pressures of the material to be dosed of up to 40 bar can be recorded in a temperature range of 5 to 50°C (voltage version) or 0 to 50°C (current version). The miniature sensor fits perfectly into the material outlet of ViscoTec dispensing systems, but can also be installed in other applications, where its small screw-in thread reduces any material losses due to dead space-optimized components. Integration into ViscoTec dispensers is quick and easy thanks to the intuitive mechanics and short cable length, meaning that the flowplus-SPT M6 J is immediately ready for use for process data acquisition.

flowplus16

The very small design of the sensor simplifies an implementation – even with small installation space. The flowplus16 can be integrated into existing processes via a luer lock connection. It is easy to clean and therefore changing materials or changings in the system configuration can be done quick and easy.

The coating of the flow channel – which is out of a perfluorelastomere – guarantees very high chemical resistance. This means, the sensor is suitable for nearly all materials in the fields of medical technology, bio technology or also electronics. And next to the ViscoTec dispensers also perfectly suitable for microdispensing technology from preeflow.

flowplus-MONITOR QC

The data can be stored on a USB stick and exported or transferred to other systems via a 15-pin sub-D interface. The evaluation unit has a 5” touch display which shows the pressure signals and limit curves in color. The limit curves and ranges can be set via a teach-in to evaluate the pressure signals.

The flowplus-MONITOR QC works together with the sensors flowplus16 or flowplus-SPT M6. The evaluation unit is easy to install and operate and works in a temperature range between +10°C and +40°C.

Applications

Life Science

In the life science industry flowplus supports especially doctors, biologists and chemists in the research and diagnosis with a wide variety of media and controls the dosage of such media.

Electronics

The electronic industry, especially the semiconductor industry demands high precision and reliability. Due to the miniaturization of components and electronic parts a maximum process safety and reliability in this industry is essential, which will be guaranteed by the fluid sensor flowplus.

Analytics

Analysts and laboratory technicians benefit from the high accurate and reliable fluid sensor by the research and analysis of various body fluids. The fluid sensor is mainly used for hightech and fully automated applications.

Industrial

Fully automated processes require and need a highly precise dosage control and evaluation of the pressure to guarantee the process safety and quality standards.

Photonics

The photonics nowadays including not only the information technology, but also the modern lighting techniques with LED’s, OLED’s and laser light sources. This micro- and nano-structured components require a maximum process reliability which is guaranteed through the dosing control flowplus.