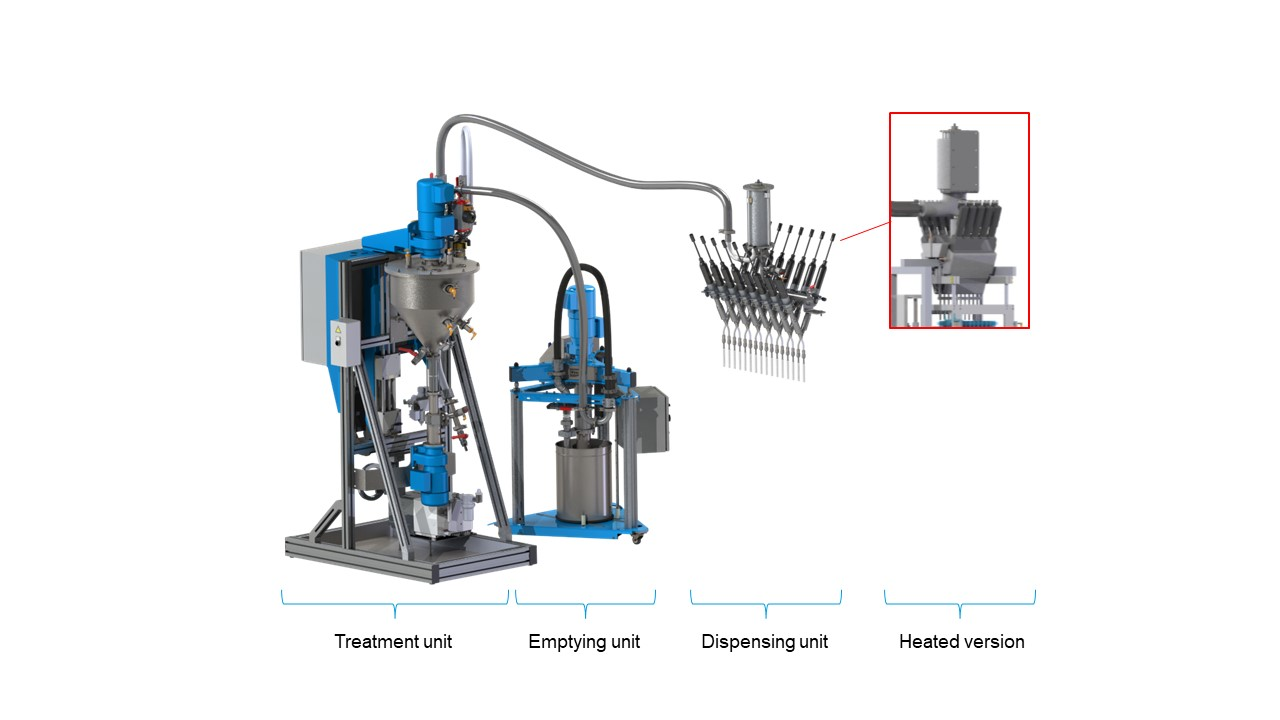

- Automation solution for filling sachets with wool wax

- Heating sleeve heats the wool wax until it is flowable

- Curved dosing needles for an extremely narrow gauge

Especially when it comes filling high-priced products, every gram counts. More than enough reason for baumannpacking – a brand of Baumann Maschinenbau Solms GmbH & Co. KG – to contact ViscoTec for a complex dosing task. The end customer – a well-known cosmetics company – was looking for an automated solution to fill sachets with a cream made of lanolin. The care product is especially needed by young mothers to care for their nipples during breastfeeding.

In the course of the project, the engineers of both companies were faced with a few challenges: For example, a quantity of only 1 ml was to be filled, which is rather unusual for liquid filling in sachets, and requires high-precision dosing. Secondly, the medical skincare product is solid at room temperature and must be heated for dosing. At the same time, the customer specified that dripping and stringing were to be strictly avoided. Only this way could it be guaranteed that the sealing process would run without any issues and avoid any unnecessary waste.

ViscoTec met the first requirement by means of corresponding laboratory tests on the 3VHD12 Hygienic Dispenser: The result: A dosing accuracy of 99.5% – which was even 0.5% higher than the value requested by the customer.

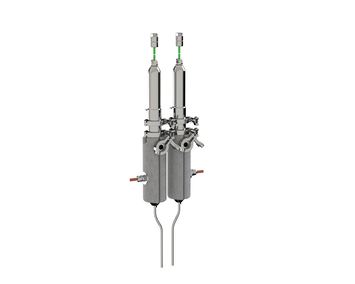

The engineers solved the second issue by heating the dosing unit to 40°C. A cuff was used, which was placed around the outside of the two vertically mounted dispensers. This constructive idea necessitated a change in shape of the two dosing needles. As a result, the two dosing needles for the two dispensers were elaborately curved into an “S” shape to fit the extremely narrow dimension. The two protruding dosing needles are heated by convection heat, which is already generated by the adjacent sealing jaws.

As for the potential problem of dripping, the engineers weren’t fazed by this: All ViscoTec dispensers have a standardized retraction mechanism that reliably prevents dripping and stringing. Thanks to the technical implementation, the cosmetics company will in future fill production volumes of an estimated 3000 sachets per hour on the baumannpacking system.