Automotive

The perfect add-on to your production process

We support you in the Automotive Industry: In the manufacturing process of conventional components as well as electromobility products. Our dosing systems offer the perfect add-on to your production process.

We achieve high precision results in potting or encapsultion of components, with the application of adhesives, sealants, casting materials and lubricants or with joining, bonding and sealing tasks. Improve your quality standards and increase your performance by using our technology.

We have put together some application examples:

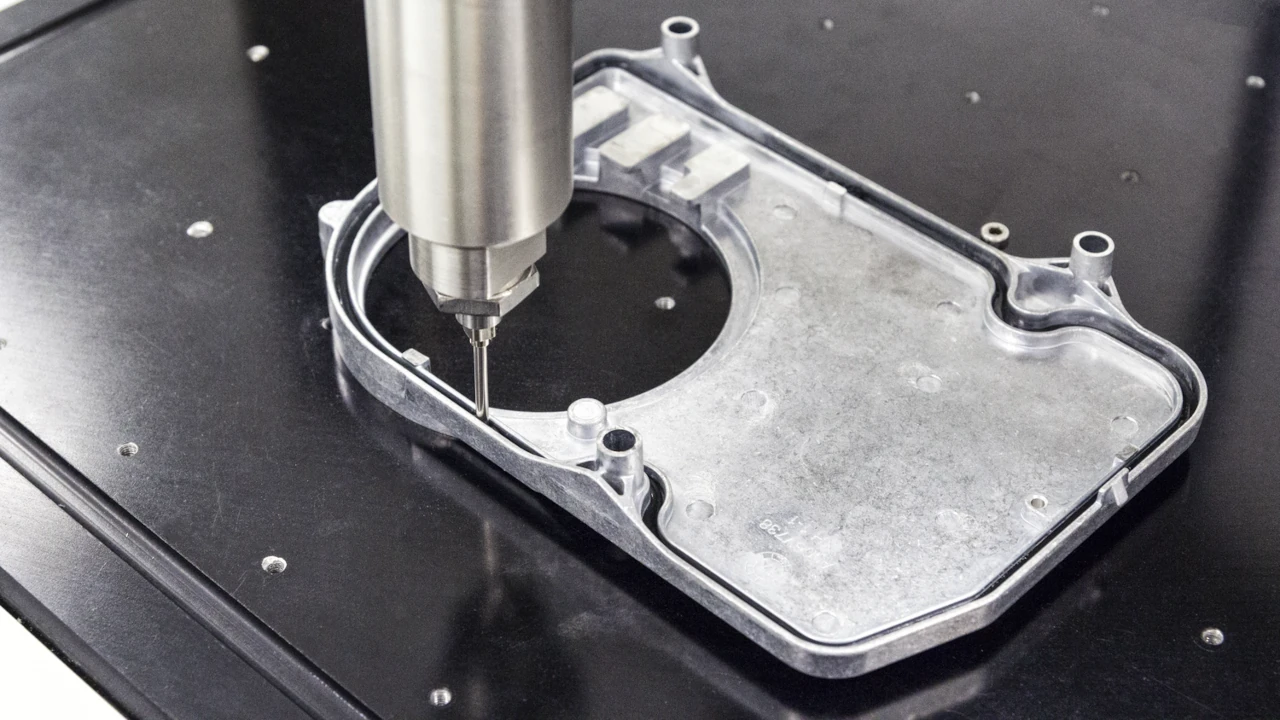

Sealant bead application

The dosing pumps and drive systems developed by ViscoTec provide solutions for applying 2D and 3D sealant beads of a wide range of media for fully automated assembly processes. Both 1-component and 2-component sealing materials with a large spectrum of material properties can be processed. In particular, ViscoTec solutions give the user the opportunity to dynamically control the delivery quantity in order to precisely synchronise the dosing quantities with the axis system’s speed with the aim of achieving consistent bead cross-sections.

Having comprehensive experience with a wide range of sealing materials and media properties in the field of sealant bead application, ViscoTec is able to not only supply components, but also to work together with users to develop an overall process for their applications. ViscoTec products for sealant bead application are already used extensively in automobile production processes, helping to manufacture engines, gearboxes, airbags, batteries and housing seals.

Flux application

ViscoTec’s material provision systems and dispensers for flux applications have been developed for high production rates and levels of dosing precision. The systems supply precisely controlled dosing quantities even at extremely high belt speeds, such as those required in the production of heat exchanger segments, for example. A selection of stator materials is available, enabling a very wide variety of media to be used and allowing the user to achieve optimum process stability in terms of the system’s chemical and mechanical resistance. ViscoTec products are already used successfully for applying flux in the manufacture of water coolers, oil coolers and HVAC/R heat exchangers.

Adhesive application

ViscoTec offers a wide range of dosing solutions for applying adhesive in metering solutions. All types of adhesive and curing mechanisms can be processed (e.g. light curing, hot curing, 2-component curing and anaerobic adhesives) with a selection of individual stator materials. Material extraction systems and material preparation systems are on offer, as well as dispensers. Having comprehensive experience in a wide range of applications, ViscoTec is able to not only supply components, but also to work with users to develop overall processes. ViscoTec products for adhesive application are used in automobile production processes, helping to manufacture belt systems, airbags and camera adjustment equipment.

Soldering paste application

Due to their very particular material properties, soldering pastes must be processed under strict observance of and adherence to important material and process criteria throughout the entire process route, from material supply to the dosing system. Their extremely high filler content and their filler weight means that soldering pastes have high relative densities, a pronounced sedimentation effect and extremely abrasive behaviour. In the area of soldering paste preparation and dosing, ViscoTec can provide complete solutions that meet all process requirements for a high-quality soldering paste dosing procedure.

Users can choose from barrel emptying systems, media delivery pumps and dosing pumps whose components can be produced in materials specifically designed for processing a very wide variety of soldering pastes. Receiver tank systems with the option to recirculate media prevent the sedimentation process from occurring and ensure a high level of media consistency during processing in order to maintain the high quality standards required in automobile production. ViscoTec products for soldering paste application are already used extensively in automobile production processes, helping to manufacture transformers, fuel lines and steering systems.

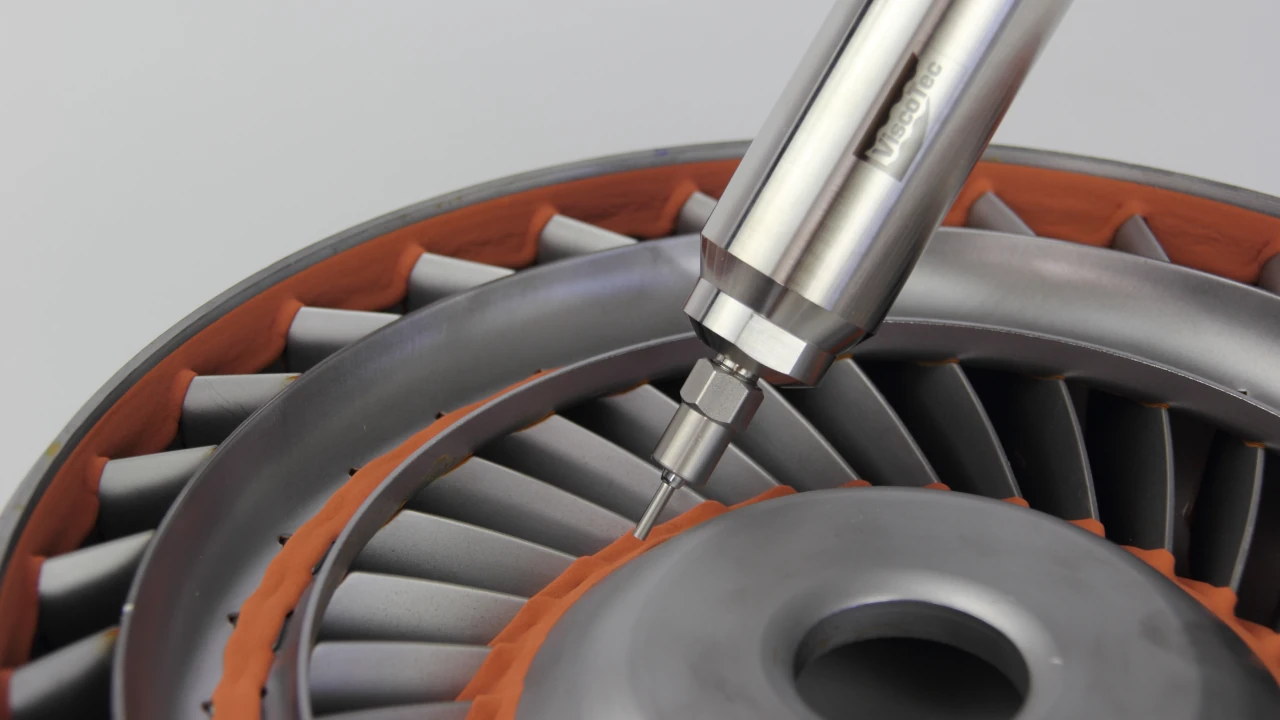

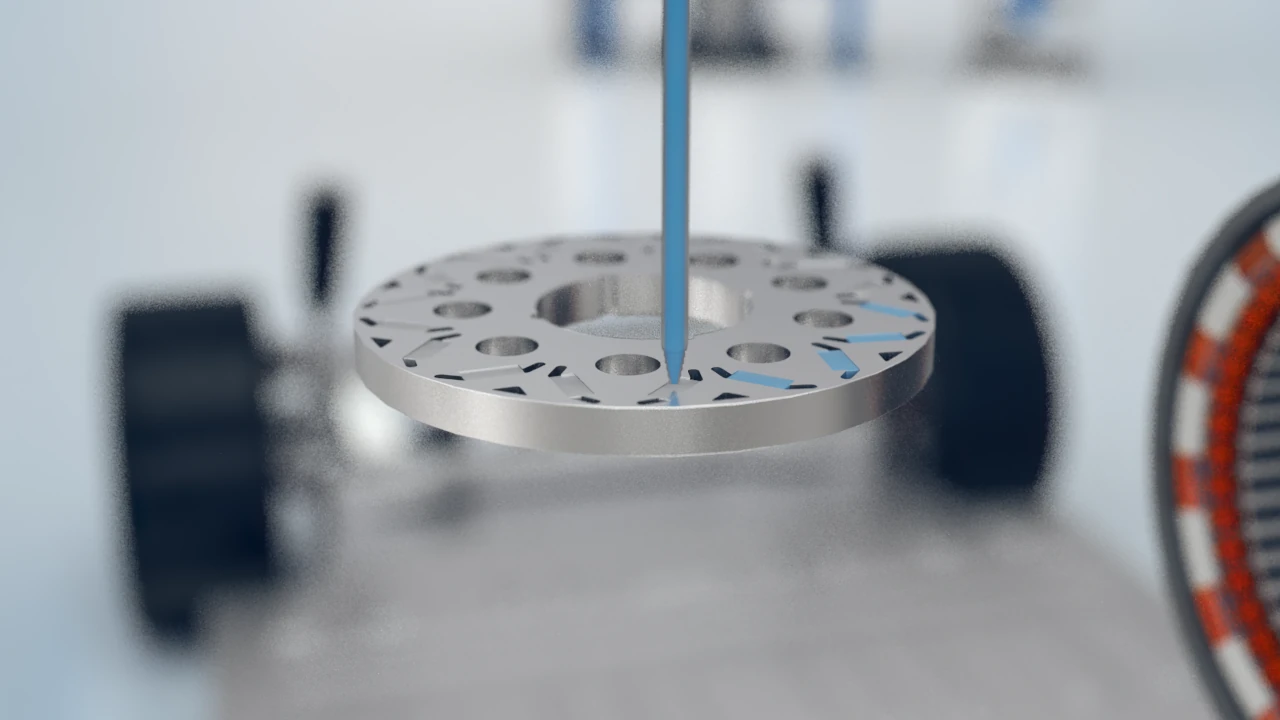

Magnet bonding

One of ViscoTec’s key technological focal points in the field of new vehicle drive systems is the bonding and potting of magnetic segments for producing rotors and stators in the manufacture of electric drives. ViscoTec dosing systems for the bonding process ensure that the media flow process is precisely controlled and that adhesive is distributed evenly specifically for the magnets used in magnetic pockets. Thanks to the short dosing cycles which ViscoTec systems can achieve, short throughput times are possible in production, even if there are lots of magnetic segments/adhesive joints. ViscoTec offers complete solutions for material extraction, material preparation and dosing for 1-component or 2-component applications. ViscoTec provides dosing systems for magnet bonding and potting in the production of rotors and stators for electric drives.