General industry

Perfect dosing solutions for industry production

General industry or industrial production covers a wide range of possible dosing applications. We offer you the right dosing solutions for your production process of machines, technical equipment, consumables and other products.

For more than 20 years we have experience with a wide range of dosing applications in industrial production with the most challenging materials. For example, in automotive manufacturing, mechanical engineering, renewable energy or battery manufacturing and many other areas.

Some examples of dispensing applications in industrial production:

Adhesive dispensing

Bonding is a joining technique that has proven itself for connections in a wide range of applications. For perfect adhesive dispensing, the use of the appropriate dosing technology is necessary. With our dosing systems we guarantee automated, reliable processes. They work independently of viscosity and dispense air bubble-free and pulsation-free. This enables you to achieve high-precision dosing results in your application: Both with 1-component and 2-component adhesives. By applying exact quantities, we create mechanically and optically perfect bonds and, in addition, unnecessary and often costly waste of material is prevented. For the core components of our dispensers, we choose selected resistant materials.

Learn more about this reliable connection.

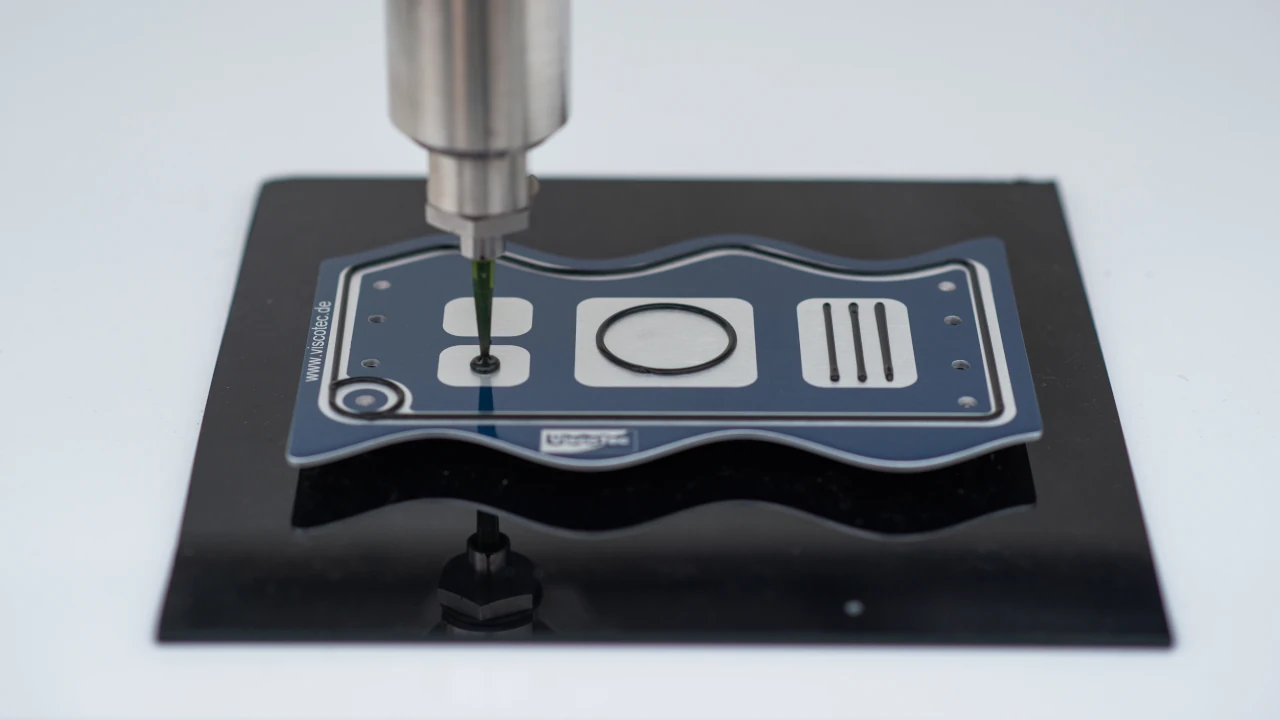

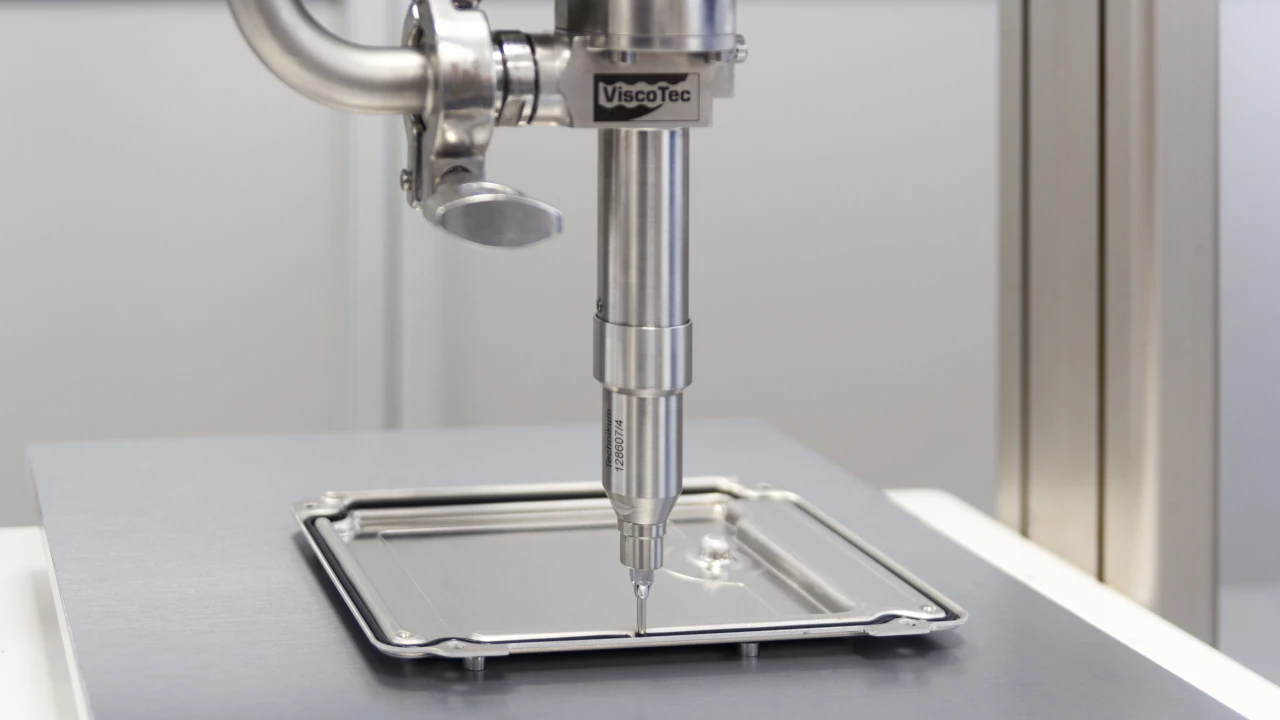

Dosing of sealants

ViscoTec dosing systems for the application of sealants are customized to the material to be dosed. High precision and an absolutely material-friendly dosage are ultimately the key to meeting the high demands from the various industries and to fulfilling the specifications. For the perfect sealing bead, it is necessary to use the appropriate dosing technology. It must be designed and used correctly. Constant bead thicknesses with clean transitions, variable dosing speeds with special geometries of the sealing bead, exact quantities and clean thread breakage – that is what our products stand for.

Find out more about sealant dosing using an example from the aerospace industry.

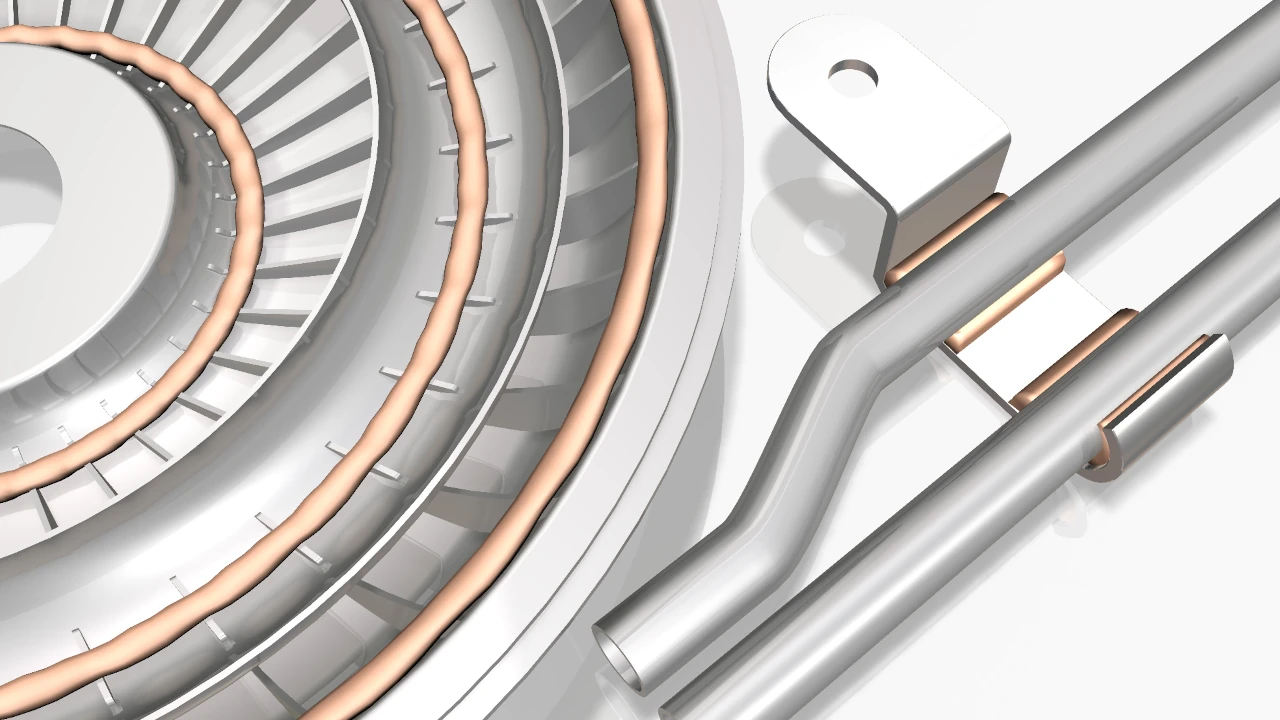

Flux application in general industry

ViscoTec’s material provision systems and dosing systems for flux applications have been developed for high production rates and levels of dosing precision. The systems supply precisely controlled dosing quantities even at extremely high belt speeds, such as those required in the production of heat exchanger segments, for example. A selection of stator materials is available, enabling a very wide variety of media to be used and allowing the user to achieve optimum process stability in terms of the system’s chemical and mechanical resistance.

ViscoTec offers not only dosing components for the flux application area, but also complete solutions that make our company’s vast process experience available to users.

Learn more about the challenges of applying thermally conductive potting compounds using an example from the automotive industry.

Soldering paste application in general industry

Due to their very particular material properties, soldering pastes must be processed under strict observance of and adherence to important material and process criteria throughout the entire process route, from material supply to the dosing system. Their extremely high filler content and their filler weight means that soldering pastes have high relative densities, a pronounced sedimentation effect and extremely abrasive behaviour.

In the area of soldering paste preparation and dosing, ViscoTec can provide complete solutions that meet all process requirements for a high-quality soldering paste dosing procedure. Receiver tank systems with the option to recirculate media prevent the sedimentation process from occurring and ensure a high level of media consistency during processing in order to maintain the high quality standards required in automobile production.

To the report on a field test with abrasive copper solder paste.

Dosing liquid paints

In the plastics processing industry, colouring with liquid paints has established itself as an alternative to colouring materials using masterbatch.

Due to the high concentration of pigment in liquid paints, very small dosing quantities must be administered when employing them and the dosing systems used must ensure a high degree of dosing precision in order to safeguard colour homogeneity in the production process.

ViscoTec dosing systems for dosing liquid paints offer products specially developed for this area, which guarantee precise control of dosing quantities even at the high process pressures that arise in plastics processing. ViscoTec provides users with complete solutions for processing these colour media, for example, in extrusion or in injection molding technology.

Here you can find more information about our technology.

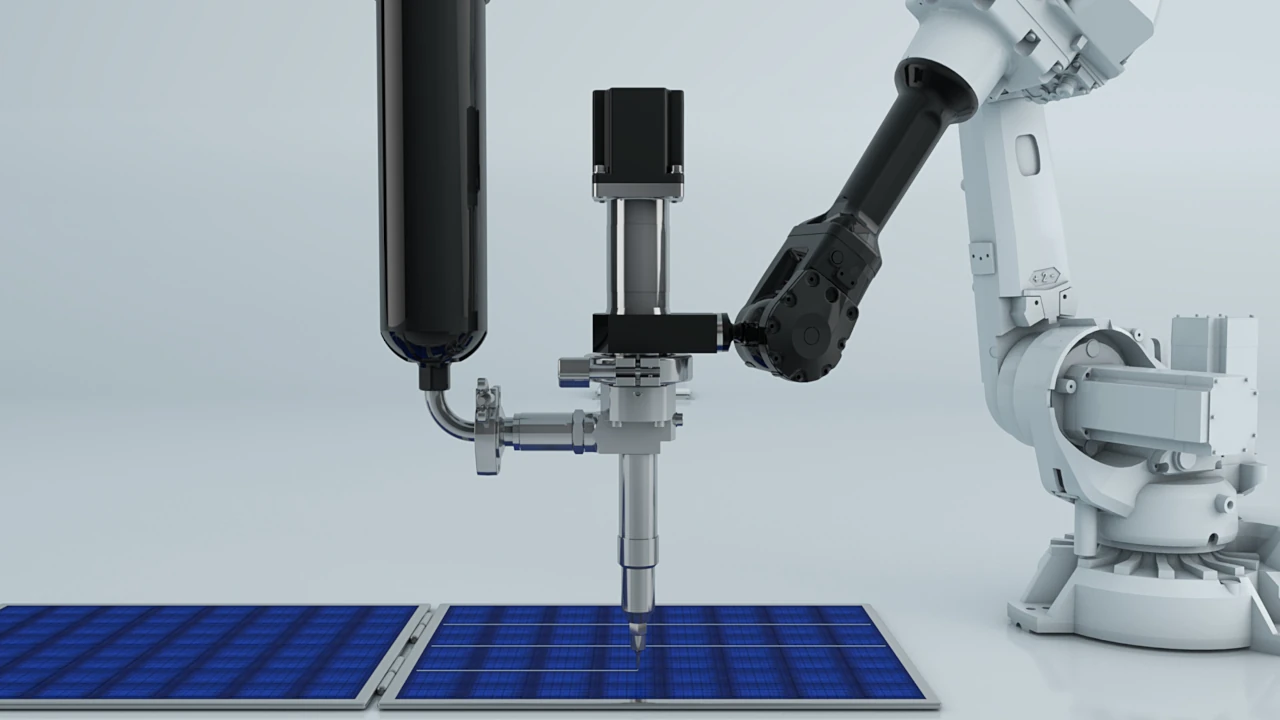

PV module production

A high degree of process quality is required in the field of module production in particular. This is because module processing quality has a significant impact on the long-term rating of a photovoltaic system and module production ties in with a high level of completion of upstream processes. Incorrect assembly will lead to considerable material losses. ViscoTec offers solutions both for frame bonding in module production and for potting junction boxes.

For frame bonding using 2-component technology, ViscoTec products ensure that the requisite high delivery quantities are achieved for bonding long edge lengths at fast axis speeds and with a high degree of accuracy. The dispensers – which are also available in a special 2-component version with a mixing head – are designed to be extremely compact and weight-optimised, so that axis systems can be dimensioned for these lower weights.

To the ViscoTec portfolio.