Pharmaceuticals

Effective solutions for the most demanding hygiene and cleaning requirements

Are you looking for the ideal dosing technology for low to high viscosity pharmaceutical products? High-precision and shear-sensitive filling, conveying, and dosing – this is what we guarantee with our products. In the Pharma Dispenser series, the requirements of the pharmaceutical industry for hygienic design and documentation are consistently implemented.

We solve complex dosing tasks. Depending on the application, various parameters are decisive. For example, pulsation-free for continuous dosing, process reliability for filling particularly highly viscous or abrasive materials, or gentle handling of solids-laden liquids and pastes. Especially when the material to be filled are solids-laden, lumpy, temperature-sensitive, shear-sensitive or sticky, conventional dosing systems quickly reach their limits performance-wise. In addition, the viscosity, dripping behavior, possible thread formation and much more must be taken into account.

Your advantages with ViscoTec:

- Up to 5,000,000 mPas regardless of viscosity

- Dosing accuracy ± 1 % starting from small quantities of 0.05 ml

- Gentle filling of structurally sensitive or abrasive material

- Programmable suck-back for defined thread breakage and drip-free dosing

- Wetted components can be autoclaved

Application examples from the pharmaceutical industry

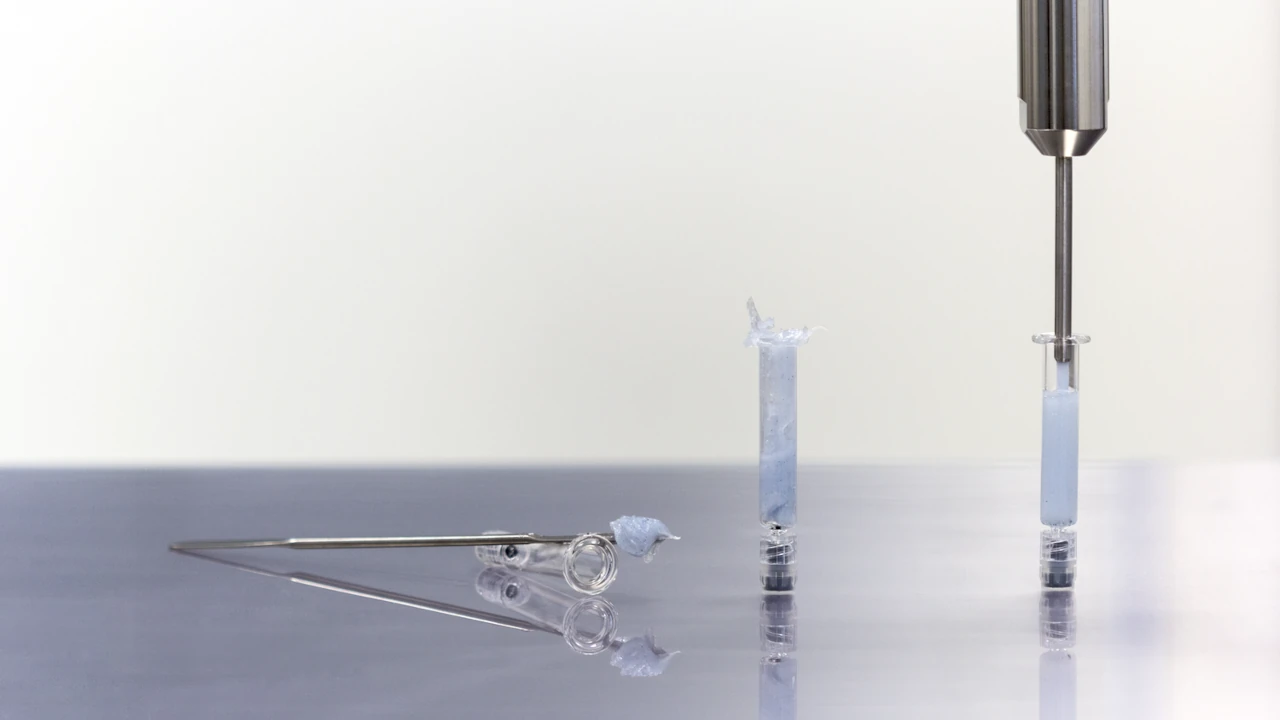

Filling semi-solid products cleanly and gently into dosing syringes

Half-hard products, so-called semi-solids, are, for example, ointments, creams or gels. The materials are not free-flowing. Nevertheless, they often have to be filled into syringes for easier dosing for the end user. Often the quantity to be filled is single doses in the µl range.

With our Pharma Dispensers, the filling of syringes can be done semi-automatically. The advantages of this are that filling is clean, gentle on the product, and highly precise. Thanks to the reversible direction of rotation or the programmable suck-back at the end of dosing, the material is retracted into the dosing needle in a defined manner. This ensures an absolutely clean thread break. Another positive effect: Contamination of the packaging with the dosing material is therefore prevented.

In a test report on filling syringes to meet GMP standards, you will find more exciting information on this subject.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDosing of suspensions containing solids

For self-dissolving tablets produced by freeze-drying, for example, the active ingredient containing water-soluble excipients, such as saccharin and polymers, is mixed with water to form a suspension. This liquid suspension is filled with precision – in the smallest of quantities – into preformed blisters and then frozen. The challenge here is to avoid filler concentration in the solids-laden liquid.

Thanks to the uniform volume flow of our technology, the suspension in the pharmaceutical dispenser remains homogeneous. In the pharmaceutical industry, the endless piston principle offers a solution for applications that are difficult or impossible to implement with piston or peristaltic pumps. Precise dosing or pulsation-free conveying can be optimally implemented: Even at high counter pressures, from liquid to highly viscous, with filled or abrasive products.

For more information on the challenges, e.g., in the production of self-dissolving tablets, click here.