Product Presentation: we would like to introduce you, for our Business Unit “Food & Pharma” the Barrel Emptying System ViscoMT-XS with a volumetric conveying pump based upon the endless piston principle.

Description

- for medium to high viscosity products (up to 7,000,000 mPas!)

- suited for abrasive, shear sensitive, solid loaded and lumpy media

- neatly wiping of the inner barrel wall by the special lip seal of the follower plate

- applicable at cylindrical, ribbed or slightly conical barrels, plastic drums or bins with inliner

- no pressing of the product at the sides due to a nearly pressureless guiding of the follower plate

- emptying speed electronically adjustable

- simple handling

- einfache Handhabung

- pulsation free conveying/emptying

- residue in the barrel: < 1%

- compact Design

Application

The ViscoMT-XS supports the following applications:

- removal of products directly out of the transport or storage container, for example: tomato paste, honey, fats, glacé icing, mascara, lip gloss, cremes, vaseline®, oinments, gels and a lot more

- pressure regulated or level controlled feeding of the products to filling machines or mixing processes

- direct dosing out of the bin (using a dosing control)

Optional design and components

The following equipment is available for ViscoMT-XS:

- two-point-pressure-control by a second pressure sensor at the end of the hose

- frame and base plate made of mild steel powder coated

- dosing control ViscoDos 3

- special design available for clean room class A

- signal lamp red-yellow-green for displaying the current operating status, also available with buzzer

- pump actuation by AC-servo drive

- alternative stator elastomers in FDA quality available (FKM, EPDM)

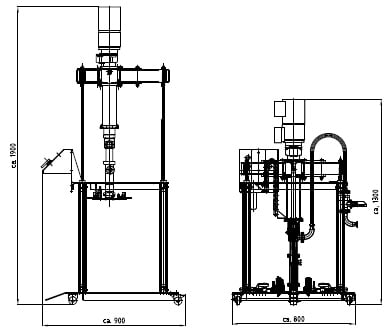

Dimensional drawing:

For questions please do not hesitate to contact us! We are happy to assist you in finding and configuring your product!