How to efficiently fill fluids & suspensions despite limited space.

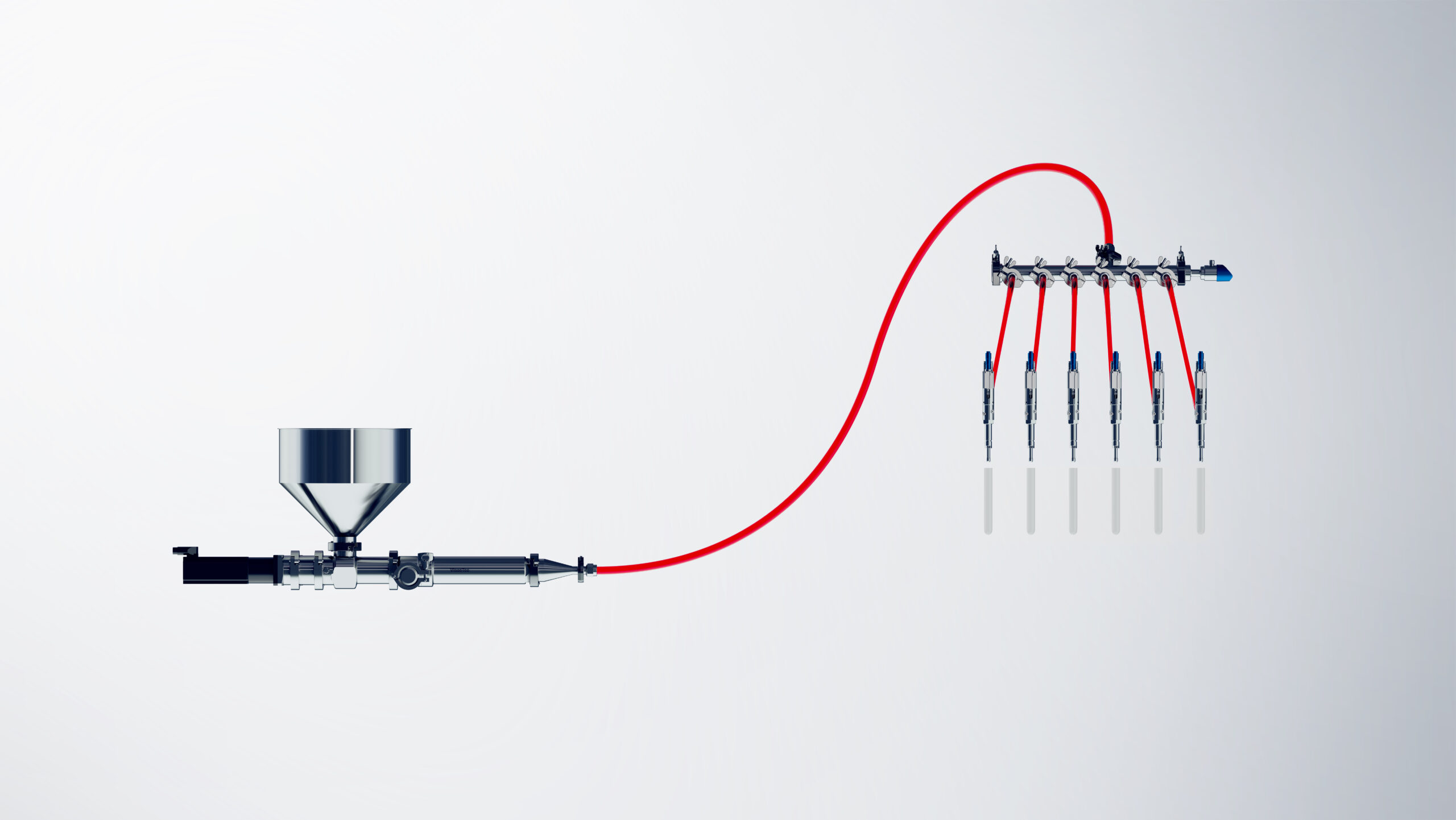

Limited mounting space due to closely arranged formats for small packaging sizes combined with high output – what could the perfect dosing solution for this task look like? Compact filling nozzles, which are installed as battery arrangements, nozzle blocks, or in multiple lines in large filling systems, are an important building block on the way to the most efficient processes possible and the optimum solution. They can be used to fill food, cosmetics, consumer goods such as detergents, or even materials in GMP-regulated industries such as medical technology, diagnostics, and pharmaceuticals quickly and precisely.

In the packaging industry, efficient machine utilization is more important than ever. Particular importance is therefore applied to the smallest possible dimensions of the dosing components in order to make optimum use of the ratio of output quantity to mountain space. Usually, however, a large output quantity stands for large dosing systems and, on the other hand, a small output quantity for compact equipment. The challenge is therefore to combine small dosing systems with the highest demands on speed and cycle time – in a small installation space. With the help of compact filling nozzles, the available installation space can be used optimally.

The advantages of compact filling nozzles:

- Compact design for easy installation

- Drip-free filling with optimized sealing principle

- Precise dosing at high filling speed

Nozzles for filling applications from ViscoTec

ViscoTec filling nozzles are made of stainless steel 1.4404 (AISI 316L) in the areas in contact with the product. Their surfaces have a roughness of Ra <0.8 µm, e-polished – suitable for hygienic applications. And they are suitable for sterilization at up to 135 °C. The FDA-compliant filling nozzles are hermetically sealed in the product chamber and free of dead space. They are easy to clean because they are completely empty. The nozzles are mounted quickly and easily using TriClamp connections.

In combination with the proven dosing pumps from ViscoTec, the filling nozzles result in a perfectly coordinated system. By using high-performance controls that enable fast switching cycles, net dosing times of less than 500 milliseconds can be achieved. The advantages of the ViscoTec endless piston principle are also of great benefit when filling at high cycle rates: The pumps operate with low pulsation, at constant pressure – without pressure peaks, and the flow rate is infinitely variable. This makes them perfect for ensuring pressure-controlled product feed to the nozzles.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSelf-regulating systems for maximum process reliability

The individualized nozzle control enables convenient calibration of the individual dosing lines via the user interface (HMI). Combined with further accessories, it can be designed into a self-regulating system if required. This allows inline reaction to material homogeneity and temperature fluctuations. This significantly increases quality assurance. The effort for quality control (for example in individual weighing) is reduced, because: The packaging units to be checked are usually removed from the running process or automatically discharged. In the worst case, the line has to be stopped for this purpose. The samples are then weighed manually. If there is a deviation from the defined target weight, all products produced since the last measurement must be reweighed or rejected. This risk is prevented with a self-regulating system!

Application examples in the consumer goods and food sectors

Whether filling cosmetics such as cremes, dosing detergent pods or dishwasher tabs: The filling nozzles are impressive, with drip-free dosing results and the continuously adjustable dosing quantity. The materials to be dosed are filled evenly and with repeat accuracy.

An individual design of the dosing system means: The system is adapted to the material to be filled and fitted to the available installation space above the packaging.

Depending on the application, a solution which could make sense would combine filling nozzles with progressive cavity pumps, for example, or just one of the two technologies. It is a matter of analyzing the respective conditions and optimally designing the process. If necessary, there is also the option of retrofitting the system into existing thermoforming machines. Due to its modular design, the dosing system can be permanently installed or designed as an auxiliary unit. Furthermore, a choice can be made between a stand-alone dosing control unit with simple signal exchange or embedding in existing control systems.

In the case of a combination of both technologies, there are two clear advantages, for example, in the dosing of dishwasher tabs: On the one hand, particularly abrasive suspensions can be dosed. This is made possible by a bypass integrated into the dosing pump. In this bypass, the material can be kept in motion during the dosing process as well as when the system is at a standstill. This prevents sedimentation of the fillers in the pump feed. On the other hand, the combination of the actual pump technology (rotor/stator principle) with the use of high-performance materials makes it possible to achieve short dosing times with long service lives of the wear parts. Another advantage: ViscoTec Hygienic pumps and dispensers can be cleaned completely within the dosing process without disassembly (CIP). Automatic rinsing is particularly advantageous, for example, when changing the color of the dosing material. It saves time because downtimes are greatly reduced.

The precise interaction of the ViscoTec dosing components is visible in the following graphic. It shows the dosing shots with a detergent of medium viscosity (approx. 1530 mPas at 20 °C). The dosing quantity is 2.5 g. The number of cycles is 100 per min. This results in maximum deviations of +0.7 % and -0.6 % over all dosing positions.

Everything from a single source: Complete dosing stations

If required, complete dosing stations including feeders and dosing control unit can be designed. Extensive tests are carried out in advance to select the best possible technology for the application in question. In the end, the customer receives a complete solution optimally tailored to his requirements: with feeding, preparation, and filling.

Flexible and individual design of the multiple filling stations is also possible. For example, VHD dispensers are used for filling highly viscous, lumpy material for the 0.1 to 20 ml range. For larger quantities from 20 to 200 ml, the vipura-PUMP is better suited. Both dosing pumps are perfectly precise and fast. For processing low-viscosity products, the dosing system can be combined with lockable multiple filling nozzles. Inlet pressure and volume flow can then be precisely controlled by the feed pumps. The following always applies: A space-saving design and cost efficiency are the main focus during planning.

The path to the perfect filling solution for your particular project

The development of the right filling solution usually starts with a theoretical calculation: Your specific required cycle times are converted into actual dosing parameters and checked against the known viscosity of the material to be filled. Depending on the packaging or even the required minimum dosing needle diameter, there are dosing pressures that must be handled.

The initial concept phase is followed by the testing phase – usually on laboratory machines. The end of this phase is reached as soon as it is ensured that everything will function smoothly later in the production process.