100 % metal-free in the product contacting area: RD-EC Dispenser meets highest requirements and expands the ViscoTec dosing portfolio

Due to the enormous growth in some industrial sectors such as e-mobility, the challenges in the manufacturing process are constantly increasing. With the development of the 4RD6-EC-MF ViscoTec even exceeds the highest requirements.

In order to prevent chemical reactions, like curing or crystallizing, within the dispense process any presence of metal particles has been eliminated in the wetted and product contacting area of the dispenser. The materials used have been selected carefully according to chemical resistance against the adhesives and liquids as well as according to highest durability towards physical wear through abrasive fillers.

Highly reactive materials like sulphuric acids, anaerobic curing UV acrylates and electrolytes that require special treatment, for example in the battery manufacturing process, can be dispensed with the highest repeatability and accuracy ViscoTec products have always been standing for.

The metal-free (in the product contacting area) dispenser can be mounted to existing ViscoTec drive technology and offers the same advantages as other tried and tested dispensers out of the portfolio from the dosing technology specialist. Available in various sizes the dispenser is available for a wide range of flow rates.

With the newest member of the RD-EC Dispenser generation, ViscoTec is excellently equipped for the constantly growing challenges and requirements in all industrial sectors.

Characteristics:

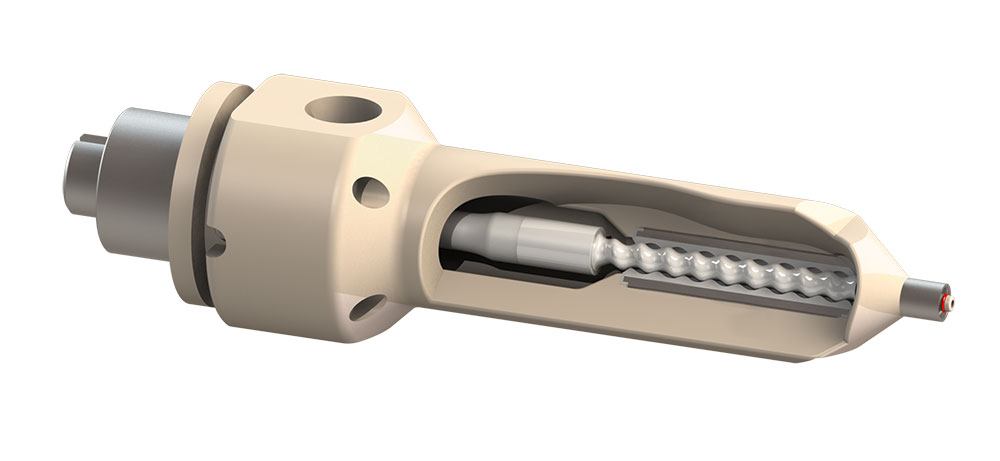

- Special polymer pump and sealing housing

- 100 % metal-free rotor shaft

- Special rotor / stator geometry

- Wide range of stator materials

- Luer-adapter for dispense tips

Suitable for:

- Anaerobic curing adhesives

- Sulphuric acids

- Acetic acid

- Bases

- Sulphur and chloride based electrolytes

- Sodium hypochloride (bleaching lye)

- Hydrogen peroxide

- lonic liquids

- and others