Dispensers from the VHD series guarantee the finest nuances in the taste of chocolate

- MARS doses additives into chocolate with dispensers from the VHD series.

- Very small quantities of less than 1 ml/min are dosed into pipes.

- Only a low investment budget is required, as there is no need for a flow meter.

Nougat, dark, hazelnut, marzipan, caramel or peppermint: There’s practically no end to the flavor variations you can create with chocolate. One of the most well-known manufacturers is the confectionery giant MARS. The most important asset of this traditional brand? Quality. And upholding this commitment to quality is a particularly challenging task in light of the 24/7 production processes involved, since additives such as emulsifiers, flavorings or milk fats need to be added continuously in minimal quantities.

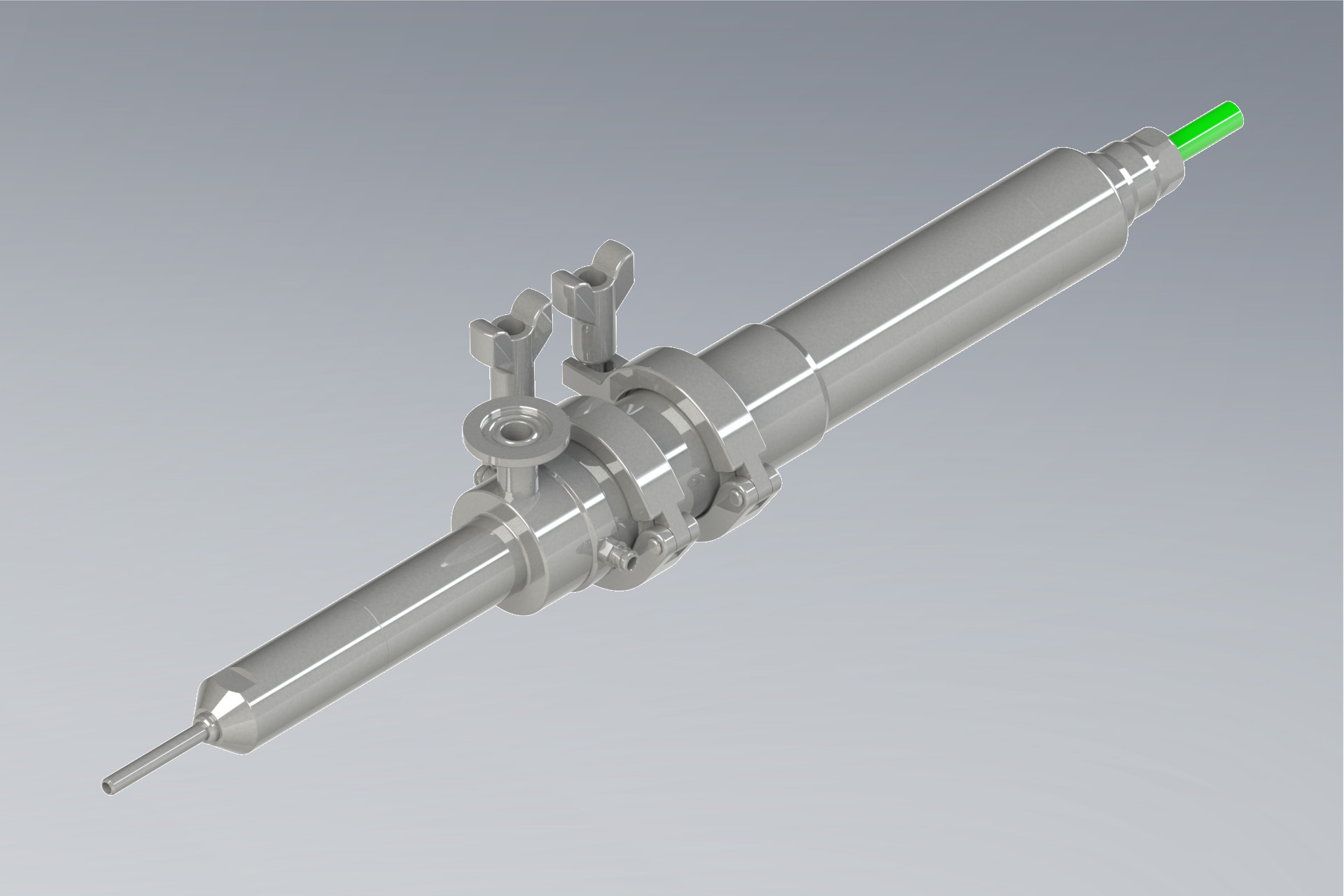

MARS has recently opened a new manufacturing line in Egypt – and has placed its trust in ViscoTec’s dosing expertise for this project as well. On this new line, additives are dosed into a pipeline using a VHD Hygienic Dispenser. In this case, MARS has connected the dosing system to the superordinate control system. However, the ViscoTec dosing technology is also intended to allow for flow measurement in the main line, in which an analog signal would be processed via the ViscoTec control unit. In this regard too, MARS is relying on the properties of the VHD Hygienic Dispenser and the compact dosing system: For one thing, minimal quantities of less than 1 ml/min can be dosed into the pipelines. For another, the technical setup and the endless piston principle guarantee continual volumetric displacement, in addition to practically pulsation-free dosing with particularly low shear.

MARS prefers these dosing applications due to the progressive cavity pumps, which – in comparison with other solutions for in-line dosing – do not require high speeds for the pressure build-up with low-viscosity media, and also since the number of revolutions is directly proportional to the discharged quantity of the additives.

The dosing system from ViscoTec therefore allows for the precise additional dosing of flavorings, milk fats and other ingredients, even with fluctuating pressures in the chocolate main line. There’s a further relevant advantage for the food corporation: The dosing system can be heated via a sleeve, which makes it possible in the first place to dose milk fat that – from experience – becomes solid at room temperatures. Another benefit: MARS has no need for additional flowmeters – which makes for a considerably lower investment budget when multiple chocolate lines are being operated.

The engineers at ViscoTec were able to establish the MARS project in Egypt in just under two months, from the order through the final delivery. The implementation and commissioning were carried out by the corporation itself. Customers always have the option to acquire the dosing system as a “plug & play” solution, or can alternatively draw on the support of ViscoTec for the integration and commissioning. For manufacturers like MARS, as well as other manufacturers in the foodstuff industry that produce substances such as oils or fats, ViscoTec dosing systems and the VHD Hygienic Dispenser are relied upon as future-proof solutions, since they guarantee precision without making compromises in terms of flexibility. The positive displacement principle of the pumps allows development departments and production officers in the foodstuff sector maximum freedom – for example, with regard to the potential adaptation of a given recipe. The ViscoTec dosing system remains process-stable, even with changing viscosities.

Thanks to the variety of these properties, dosing systems with dispensers from the VHD series are optimal solutions for the food industry, as well as for the pharmaceutical sector and cosmetics manufacturing. All these sectors require solutions for dosing minimal quantities of an extremely wide range of media into pipelines or extruders – to the highest levels of precision and while adhering to the highest hygienic standards.