Semi-automatic syringe filling machine saves time

In the dental industry for example, many consumables such as etching gels, whitening gels and composites are filled into disposable syringes which have a Luer Lock connection. Often the filling of the syringes is done manually and is therefore very time-consuming. The semi-automatic bench top dosing system from ViscoTec can hereby help. It offers the user ease of handling and saves time. For example, net dosage times for 1ml below 1 second depending on the viscosity of the material are possible.

Easy handling of the syringe filling equipment

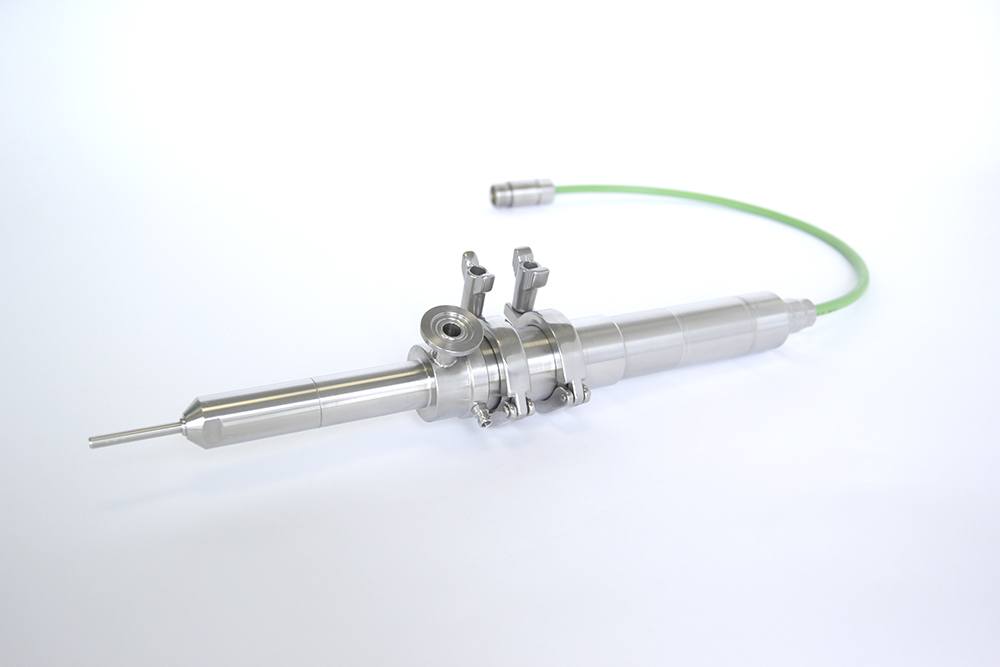

The operation is very simple: For filling, the user connects the syringe to the system via the Luer Lock connection and the dosage is started by activating the foot switch. Thanks to the proven progressive cavity technology of the Pharma Dispenser, highly viscous or abrasive materials such as polishing pastes or bone replacement materials can be dosed with great high precision. A power supply and compressed air are all that is required for on-site installation. It is fed via a cartridge system, which is available in various sizes up to a maximum of 950 ml.

Cleaning takes place after simple, tool-free, manual dismantling or in the cleaning machine.

Learn more about the application in this video:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFilling dosing syringes precisely and gently

Due to the small quantities that have to be dosed, an absolutely exact filling of the dosing syringes or containers is necessary. Conventional filling technologies reach their limits here. With the Pharma Dispenser we offer a perfect solution for filling various syringes.

Due to the often high viscosity of the materials to be dosed and the comparatively small opening on the syringes, high dosing pressures occur, which are handled very well by the pressure stability of our endless piston technology. At the end of each filling, the medium is withdrawn, e.g. from the syringe cone, to keep it clean. To do this, the direction of rotation of the dispenser is changed and the dosing material is retracted into the dosing needle in a defined manner. The suck-back function is also particularly convincing for materials with difficult thread breakage. The quantity, speed and acceleration can be individually adjusted according to the requirements of the product. The medium thread breaks off in a defined manner – very good and absolutely precise dosing outputs are the result. Together with you, we determine the optimum dosing and filling parameters specifically for your application.

A further, very exciting field of application for our syringe filling equipment is the filling of semi-solids in ready-to-fill syringes. Here you can read a detailed report about it.