Dosing technology from ViscoTec: Compact design, short cycle times

The requirements for fully automated filling lines are diverse, but the following applies in all cases: Only an economical system is beneficial. High cycle rates and the required output rate with constantly precise dosing results must be met. This is a challenge, especially when dosing low to high viscosity liquids, and may create critical stages in the process. To achieve an ideal implementation, precise dosing systems are necessary – also in the form of application-specific multiple filling lines for packaging systems.

Your advantages at a glance:

- Compact design, square dispenser

- Short cycle times of 0.5 seconds (depending on the material)

- Easy integration in filling lines

- Filling of watery to high viscosity materials

- Optimally suited for dosing volumes of 0.1 to 20 ml

Multiple liquid filling lines

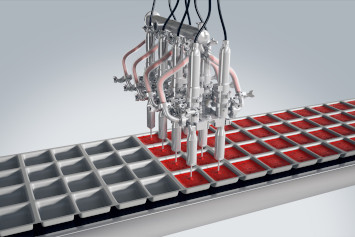

The multiple liquid fillers must be integrated into the filling lines as easily as possible. Tool carriers or format plates often have narrow tolerances, so a compact design of the dosing valves is necessary. In response to market requirements, ViscoTec has developed a square dispenser, the Hygienic Dispenser VHD-Q. Thanks to their square shape, the dispensers, which dispense regardless of viscosity, can be form-fittingly joined next to each other – with a minimum need for space – and in a modular design. The liquid is supplied via manifolds which are directly connected to the dispenser – without hoses or pipes. In this way, any number of dosing points can be achieved in one “block”.

Optional connection by hose or pipe

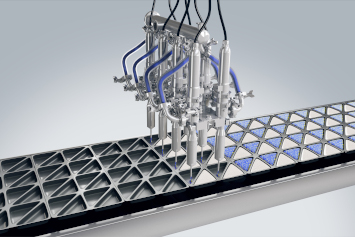

The dispensers can also be placed next to the tool carrier and connected to a dosing needle directly above the container via a hose line or pipe. In this way even smaller tolerances are possible. The dosing needle is adapted to the format in terms of length and diameter. A defined string break is achieved by an adjustable suck-back at the end of the dosing process and dripping is prevented. Positive shut-off nozzles or filling valves can also be used to further optimize the dosing time. If required, the dosing components can be temperature controlled via optional heating systems such as heating sleeves or cartridges. This can be particularly advantageous for products with stringy liquids. The dosing result is improved, and the dosing time is kept to a minimum.

Short cycle times of 0.5 seconds

Due to high-performance materials in the filling pumps and powerful servo motors, short cycle times of 0.5 seconds can be achieved for watery to medium-viscosity products. With a dosing accuracy of +/- 99 %. Product or color changes can be easily implemented with optional connections for circulation piping or CIP systems. Circulation may be necessary to prevent sedimentation in solids-laden liquids such as suspensions. The robust dosing systems can also be used in 24/7 production facilities. There they excel, for example, with their high stability and low maintenance.

The compact dispenser for multi-lane filling lines can be used for a wide range of applications. Due to its hygienic design, it can be used for household products such as detergent pods or cleaning agent tabs, as well as for food products including food supplements or fruit purees. It can also be used for highly viscous medical products such as blood separating gels and is optimally suited for dosing volumes of 0.1 to 20 ml.

The economic benefits of fully automated systems depend not only on cycle rate and precision, but also on the diverse variety. This is because it enables a flexible and quick response even with smaller batch sizes and an increased number of batch changes. Thanks to the easy cleanability and the proven ViscoTec endless piston principle, ViscoTec customers are able to process a wide variety of products with only one dosing system: From liquids to pasty substances – abrasive, sticky or solids-laden. Unnecessary interruptions in production, due to set-up times for replacing entire dosing systems, are a thing of the past.