World of dosing

Technology news

Latest dispensing information

Whitepapers, Technical Articles & more

Let’s keep you up to date!

ViscoTec Introduces Its New Puredyne® Brand

Proven progressive cavity technology combined with patented single-use cartridges in bioprinting printheads Following the success of preeflow, ViscoTec has expanded its portfolio and launched another brand called "Puredyne". With the launch of the new bioprinting...

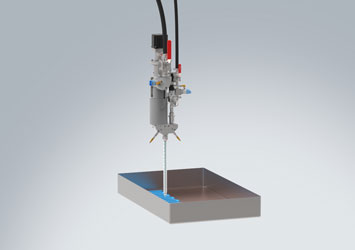

Application of Thermally Conductive Potting Compound in the Automotive Industry

Including monitoring of the quantity applied For a customer project in the automotive sector, Strama-MPS Maschinenbau GmbH & Co. KG from Bavaria, Germany, was looking for the right dispensing technology to implement in a production line. The dispensing application...

Dispensing Expo: Experience Dispensing Virtually

3-day event promises exciting technology updates. Never change a running system - there is no better way to express the thought behind the repeat of last year's very successful Dispensing Expo. On October 26, ViscoTec will once again open its virtual doors to the...

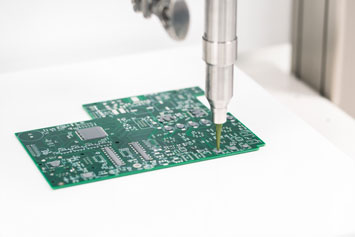

Dispensing Abrasive Thermal Paste

Thermal management in printed circuit boards ViscoTec dispensing pumps have already proven themselves in numerous applications as the optimal tool for handling highly abrasive materials. Dispensing tests were carried out for one customer with its new 1-component...

Change in Management at ViscoTec

Franz Kamhuber to succeed Georg Senftl. With a change in top management, ViscoTec is writing a new chapter in its highly successful company history. The long-standing Commercial Managing Director, Georg Senftl, will retire at the end of 2021. He will be succeeded on...

2VMP22-3D: Larger Dispensing Volume with the Same Size

Different stator materials and a separable rotor assembly add to the advantages of the 1-component dispensing pump The 2VMP22-3D facilitates the dispensing of single-component fluids and pastes in larger quantities. Compared to existing dispensing pumps of the VMP...