Whitepaper

Latest Technologies and Applications

Additive Manufacturing with Silicone

For some time now, additively manufactured components have been used for more than just prototyping. Their great potential is also used in pre-series construction and for production parts. For technically usable components, the material properties are of crucial relevance. In this area, 3D-printed components can only compete with conventionally manufactured ones if they also have the same mechanical and chemical properties. Biocompatibility, thermal resistance and, of course, very high elasticity make silicone indispensable for very many applications.

Honeycomb Potting

Profitability is also the top priority in the aviation industry. To get aircraft from A to B economically, they have to be as light as possible, meaning that they consume less fuel. The airlines save money and at the same time the environmental impact is reduced. Despite their low weight, components in aircraft have to meet high safety and stability requirements. And lightweight often means thin and not stable.

Heat management in liquid form, thermally conductive materials

Heat management is an important aspect for the safe and efficient functioning of mechanical and electrical devices, even if this is often not visible from the outside. Driven by the trends of electrification, digitalization and miniaturization, this process is becoming increasingly important. This goes hand in hand with steadily increasing requirements from a technical and commercial perspective.

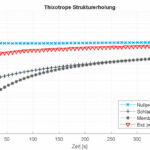

Empirical estimate of shear rates – Dispensing pharmaceuticals without harming the product

Various technologies are available for the dispensing and filling of pharmaceutical products. However, caution is required especially when handling highly viscous and structurally sensitive materials. Many require very careful handling to ensure safety, stability and efficacy. But what technology is best to avoid harming the product? And how can the available technologies be compared?

Dispensing Technology for Fuel Cell Production

ViscoTec takes care of many different applications in the production process of a fuel cell, such as bonding and sealing. Extensive dispensing tests were carried out to obtain particularly high-performance connections. The result: Reliable connections for particularly long-lasting cells and easy assembly, coupled with simple production technology. Fuel cell technology has the potential to replace batteries, generators, and emergency power units in numerous applications.

Liquid Adhesives: The Requirements for Adhesive Technology

The use of adhesive creates a reliable bond. This has now been demonstrated in almost all industries, in the most diverse applications. But the demands on the type of bond are constantly increasing. And these demands also need to be met in the future. Material combinations are the key to success. This is where the potential of adhesive bond comes to light: Because only with them is it possible to connect different materials permanently whilst fully retaining their properties.

Trickle impregnation of electric motors

Trickle impregnation of rotor and stator – an important process in the production of electric motors. Especially with the electrification of the powertrain in the automotive sector, the demand for durable engines with maximum power density and low noise emissions is increasing. This white paper deals with automation solutions, especially for impregnating electric motors and the advantages of the various resin impregnation methods.

Sealing over the course of time

Reduce material waste and increase efficiency: The dispensing and application of sealant and sealing compounds in conventional aircraft construction is a complex process that can be significantly improved in many ways. In the construction of aircraft in the early 20th century, seals in aircraft tanks or fuel lines, for example, were usually rubber sheets cut into shape.

Additive manufacturing with liquid materials

Evaluation of different additive manufacturing processes with liquids and pastes: The use of additive manufacturing processes is increasing within industrial applications, as they bring some significant customer benefits compared to conventional processes. Additive manufacturing is based upon the layered structure of a component. The production time therefore depends on the volume to be applied to the component.

Perfect dispensing of two-component silicones

Silicone has become one of the most versatile connecting materials and can be used across a huge range of applications. Although many users are only familiar with standard commercial “silicone sealants” in plumbing, the material has considerably more potential uses. Meanwhile, the ongoing development of silicones is opening new applications in the industry for future production methods.

Personalized Food as part of our lifestyle

“Digitization” and “networking” are everywhere. New technologies play an important role in this and are also revolutionizing nutrition and fitness. Food production is also affected by our health-conscious way of life, as part of the personal lifestyle, because eating habits are closely related to the fitness hype. The biggest challenge that the industry needs to address is the conversion and adaptation of food production and related processes.

Additive manufacturing processes are changing the industry

A comparison of 3D printing processes: 3D printed or additive manufacturing components are revolutionizing industrial production – and have been doing so for a long time. Various processes are establishing themselves on the market and breaking up the structures of conventional production processes. To produce an object there are now numerous, different possibilities available.

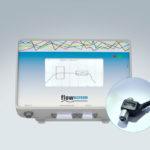

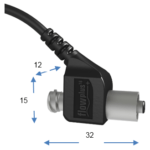

Integrated process monitoring of dosing pressures

The relative pressure sensor flowplus16 is specially designed for the requirements of semi and fully automated dosing processes. With the help of the Luer system, it can be integrated into a wide variety of applications in a space-saving manner. flowplus16 provides a temperature-compensated, linear output signal in the range of 0.1 – 10 volts and is ideally suited for implementation in industrial processes with higher-level control (PLC).

The flowplus pressure sensor – physical principles and function

Sensors (from the Latin “Sensire”) are devices by means of which it is possible to detect physical or chemical properties of materials. As human beings, we are not able to perceive these properties accurately (e.g. pressure), without technical assistance, and therefore only estimate them. For this reason, measuring devices in the form of sensors, transform these properties into readable quantities which can be processed further.

Solving complex pharmaceuticals dosing tasks

Dosing and filling applications with progressive cavity pumps: In the field of dosing and filling in the pharmaceutical industry, one usually thinks of water-like, non-viscous products such as solutions used for injecting. For the most part, these can be filled with a high degree of process reliability using hose pumps, rotary piston pumps and time pressure systems.

Comparison of different metering pumps

What characteristics are required of a metering pump that is to process highly viscous and abrasive media that are sensitive to shear with a high degree of process security and, at the same time, tolerate changes in the flow properties of these media? The solution: a metering pump in accordance with the positive displacement principle. A progressive cavity pump (PCP for short) is a well-known example of a pump of this type.

Plastics: Fillers, anti-friction properties & wear

Caused by the high requirements on components subjected to electrical, mechanical or thermal stress in various industries, the combination of diverse properties in the same plastic material is vital. Achieved by the addition of multifunctional fillers, the corresponding procedure is identified as additive applications. The high share of fillers and the corresponding abrasiveness of these additives place huge demands on the processing dosing technology.

Filling pharmaceuticals that are viscous or contain solids

Conventional filling technologies such as piston or peristaltic pumps reach their limits when filling small quantities of viscous, medical or pharmaceutical products – such as gels, ointments, hyaluronic acid and polymers – with precision. Solids and abrasive products are used to be effect in these types of pump. It is exactly for these types of application that filling pumps using the endless piston principle are particularly suited.

Filling of viscous Food & Cosmetics in tubular bags

The demand for small packaging sizes and sample packages has dramatically increased during the last years. According to the Confederation of German Food Industry this trend will still grow in the next years. Therefore the process-safe and precise filling of liquids in tubular bags is getting more and more important. Complete machines and systems which are using filling systems based on the endless piston principle could fulfil the high requirements.