Filling pharmaceuticals that are viscous or contain solids

Independent of viscosity, shear-sensitive and high-precision

Advantages of the endless piston principle

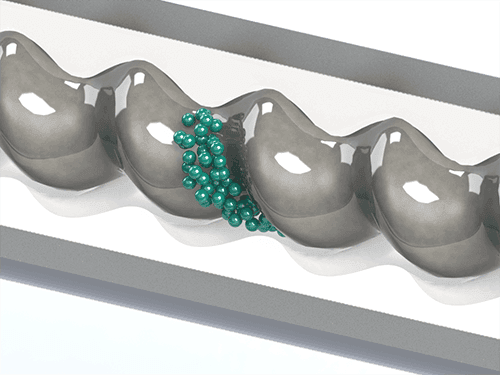

This technology belongs to the group of the rotary positive displacement pump. The stainless steel rotor moves eccentrically in the elastomer stator. Chambers are formed through the interaction between rotor and stator. The size of the next opening chamber remains constant during rotation, so that there is no compression of the pumped product. The endless piston geometry allows for a precise, gentle and pulsation-free product flow.

Filling viscous pharmaceuticals from 0.2 ml

To achieve a precise dosing of a small quantity, there is a basic requirement that the thread must tear off in a defined and clean manner. This is most likely true for aqueous liquids – but for viscous products this is not often the case. Many products like creams, gels and ointments pull long threads from the end of the dispensing needle to the particular packaging unit. Uncontrolled and unwanted dripping of low viscous product from dosing needles can occur with certain parameters (for example a dosing needle with a wide diameter, pressure release over the dosing needle between the dosing shots).

For pumps based on the endless piston principle, the path of the fluid is blocked after dosing. Thanks to the chambers inside the rotor stator system, dripping of the product is prevented. A valve inside the dosing needle or pump is therefore not necessary. Due to the reversible direction of rotation, the retraction can be adjusted after dosing. This function helps to obtain a completely clean cut of the thread. Volume, speed and acceleration can be individually set according to the requirement of the product. The thread is cut with precision – therefore very good and highly accurate dosing results are achieved. A further positive effect: after each filling process, edges of the packaging or parts of the filling machine are not soiled or contaminated by the product.

Industry-safe dosing results through high counter pressures

These benefits can be best utilized in glass tubes (up to 400,000 mPas), for example, in the dosage of blood separating gels. The thread breakage of these gels is comparable to that glue. By using retraction and dedicated parameters in the procedure, the net dosing duration – including cutting the thread – is reduced by 50 %. Therefore greater cycle times can be achieved at the filling machine.

High pressure can occur through the high viscosity of the medium and the small diameter of the dosing needle, however, this is easily managed with the endless piston principle. High pressure also builds up when filling polymers into dual chamber syringes or when feeding certain media into extruders. Again, the pressure resistance of the endless piston technology of up to 20 bar can be used to best effect.

Gentle filling of products containing solids

When filling pharmaceutical products containing solids, it is often a challenge to find the appropriate dosing technology. This is where the endless piston principle is well suited due to its particularly shear-sensitive production. The product remains homogeneous due to compression-free conveyance. In the case of suspensions, there is no separation of solid matter or binder inside the pump. In the preparation of freeze-dried tablets, for example, suspensions are filled in blister packs in small amounts of 0.2 to 1 ml. The low-shear filling of this suspension can be achieved through the use of endless piston technology. Even abrasive media, such as pastes, can be filled or conveyed pulsation-free due to the laminar flow in the endless piston technology.

In the pharmaceutical industry, this technology offers a solution for applications that piston or Peristaltic pumps cannot offer, and if so, only with difficulty. Precise dosages or pulsation-free conveyance can be achieved even with high counter pressures, from liquid to highly viscous, with filled or abrasive products.