Filling of viscous food + cosmetics in tubular bags

Process safe and precise filling of different liquids

Perfect dosing accuracy is the basic requirement for filling tubular bags.

The demand for small packaging sizes and sample packages has dramatically increased during the last years. According to the Confederation of German Food Industry this trend will still grow in the next years.

Therefore the process-safe and precise filling of liquids in tubular bags is getting more and more important.

Complete machines and systems which are using filling systems based on the endless piston principle could fulfil the high requirements and demands for the dosing technology perfectly.

Advantages of Endless Piston Principle at filling applications

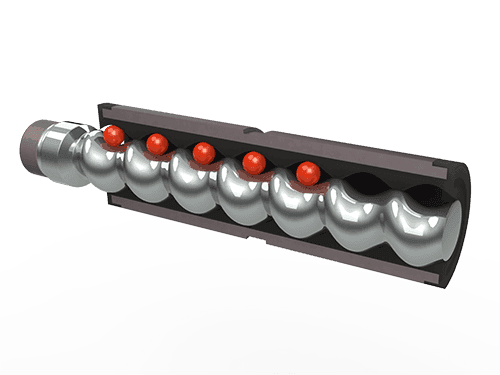

Endless Piston Principle Pumps (= Eccentric Screw Pumps / Progressive Cacity Pump) belong to the group of rotating positive displacement pumps and are based on a volumetric pump technology. The operating mode is similar to an endless piston, which pumps the liquids from the suction side to the pressure side and therefore creates a pressure difference. The core part is a volumetric dosing pump. The combination of an eccentrically moving rotor in a stator results in dosing characteristics which correlates with an endless moving piston.

The rotor-stator-geometry of the endless piston principle allows a shear sensitive dosing process – even for filled liquids.

The dosing geometry allows having a constant volume per each revolution of the rotor (proportional to the angle of rotation). It is possible to reverse the flow-direction by changing the direction of rotation. Therefore the volume is clearly defined by the angular degrees. This technology offers a pressure-constant, linear pumping performance curve. With this curve it is possible to define exactly the ratio of revolutions, time and dosing volume. This guarantees a theoretically dosing accuracy of +/- 1% at the outlet of the pump (depending on the fluid) and in most of the cases even less.

Another advantage of this technology is that the created cavities are always constant during the whole movement. These cavities offer the chance to pump and fill liquids with fillers, particles or pieces. Another advantage compared to other pump technologies: In more than 95 % of the applications it is not required to use closing valves as the pump uses a suck-back (short reverse movement of the pump at the end of the dosing process). By using this suck-back, it is a clean process without dripping or stringing and even difficult, high-viscosity liquids could be dosed in a safe and reliable way. There is no stress on the liquid, no pulsation and no interruptions in the dosing process.

Use in Tubular Bags Filling Machines

All these advantages are used in the manufacture of tubular bag filling machines, e.g. VFFSM-machines. They rely on the easy, process-safe and precise filling results of endless piston pumps. A typical configuration is the assembling of the pump on top of the machine. The pumps are filled by simple hoppers or by barrel emptying systems. A filling nozzle at the end of the pump is mounted together with the forming tube of the tubular bag filling machine. If the nozzle is too long (and therefore the suck-back effect is not enough), the filling nozzle could be closed with a plunger in order to avoid dripping or stringing of the liquid.

Liquids are dosed in a very sensitive way and exactly in tubular bags. If necessary the complete system (hopper and pump) could be heated up – according to the requirements of the liquid. However it is not necessary to heat the liquid just to reduce the viscosity: The endless piston principle is independent from the viscosity and therefore the viscosity does not influence the filling results. Basically the advantages of the technology could be particularly proven with high viscosity liquids.

In comparison to the classic piston filling systems this is an additional advantage. It guarantees that the customer could use his machine flexibly without retrofitting it. Many piston pump systems reach their limit at a certain viscosity range. The only chance is an extensive modification of the system. Progressive cavity pumps however could be used for any viscosity range – starting from water to firm pastes and crèmes.

Cycle times less than 1 second

ViscoTec dosing and filling pump RD Hygienic

The endless piston pump is also convincing at cycle times, which is a very important topic: Compared to piston pump systems the endless piston pump could reach similar cycle times and is as fast as them. So given perfect conditions, the endless piston pump could reach cycle times of 0.4 seconds. Additionally, it is not necessary to refill a piston for the endless piston pump. This principle offers a continuous dosing without interruptions. Therefore the filling process could be optimized and automated in a perfect way.

Another advantage of the endless piston technology is the simple handling for all applications: e.g. the dosing quantity could be modified by only changing the speed of the motor. The pump with the motor is easily integrated in the superior PLC of the filling machine. During the filling process the pump solely needs a start signal from the PLC.

These advantages and benefits of the endless piston principle are tremendous: Meanwhile a filling process with these systems is the industrial standard. Worldwide customers are using this technology for all different kinds of filling applications, e.g. sauces, spice essences, fruit- and vegetable pastes, soups, marinades, dressings, cosmetic gels and crèmes, pet food and many more.

Therefore different types of endless piston pumps are used, depending on the filling quantities. Even small or micro-quantities could be realized, e.g. 0.5 ml for each bag (with the dosing and filling pump RD Hygienic from ViscoTec.).

Endless piston systems (to the product overview) are trend setting: Today packaging are getting smaller and smaller, but the output of the bags and packaging in general is rising. Therefore production processes need flexibility. Only the endless piston pumps systems could offer this in a perfect way.