Heat management in liquid form, thermally conductive materials

State of the art, challenges, and opportunities using progressive cavity technology

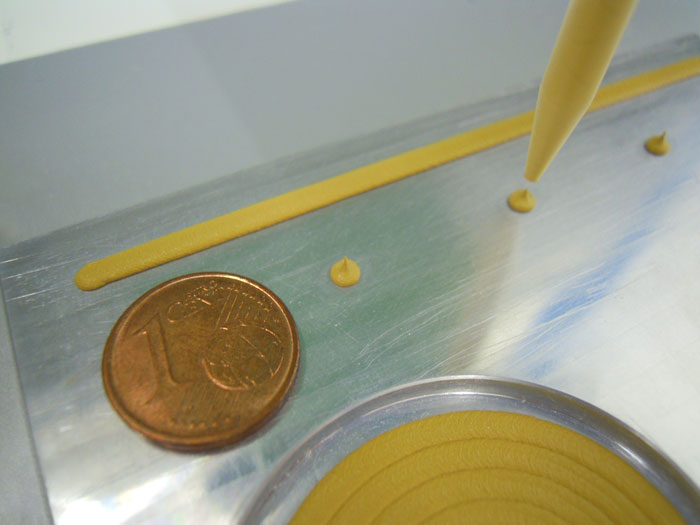

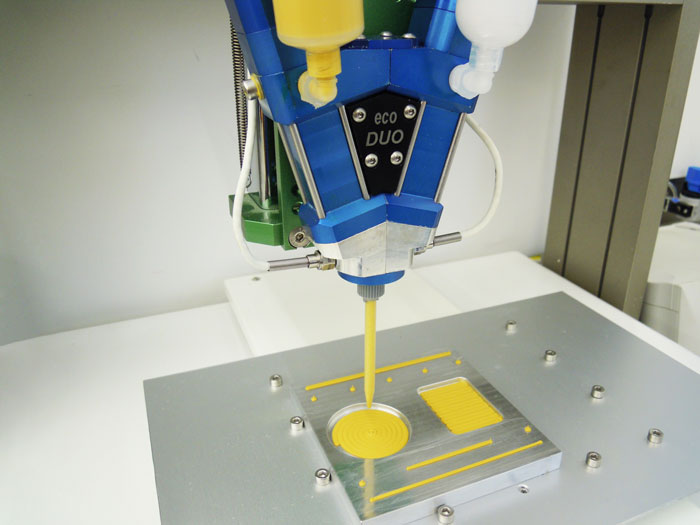

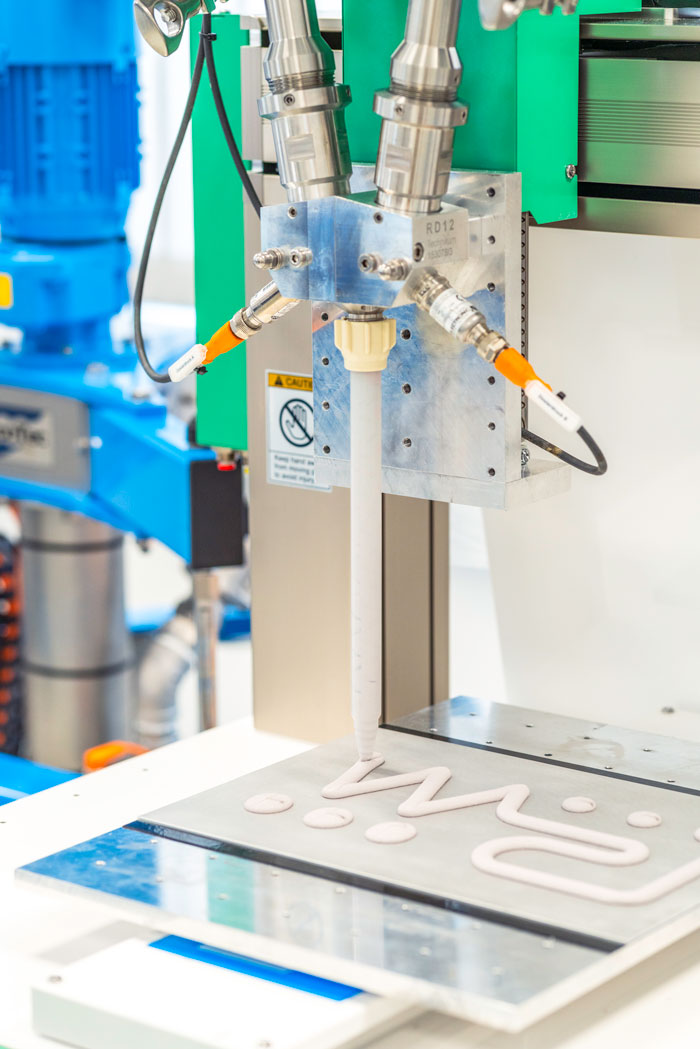

Examples of dispensing tasks in heat management:

Characteristics of heat-conducting materials and the resulting challenges

One part of heat management design is often that thermally conductive material be applied in liquid form, as a paste or an adhesive for example. The term “thermal interface materials” (TIM) has become established for this type of material. Their task is to thermally couple two or more components with each other to dissipate the heat that is generated. Coupling in this way may be necessary due to manufacturing tolerances, design constraints or a combination of these. In order to be able to guarantee the thermal conductivity (W/m*K), the above-mentioned one- or two-component pastes or adhesives are sometimes loaded, to a large extent, with fillers. These can be of ceramic or metallic nature. Depending on the filler material used, the desired conductivity and the cost factors, these fillers can be of different shape and size. When applied, they often exhibit abrasive behavior, which in turn can lead to comparatively rapid wear of the dispensing equipment used. This can lead to an unstable process if the setup (material, dispensing equipment, and process parameters) is not properly matched. The result can be production interruptions and increased spare parts and maintenance costs. And that would be reflected in the unit costs.

Proposed solutions for the process-safe application of thermal interface materials

Due to the continuously growing importance of heat management and the increasing demand for TIMs, various approaches are currently being pursued to further improve the handling of such pastes or adhesives. One possibility is to process these materials using progressive cavity technology, both in the supply and treatment, as well as in the application onto parts. During this process, the material to be dispensed is conveyed purely volumetrically and continuously by means of a rotating rotor and a fixed stator. This process is characterized by its low-shear and therefore material-friendly mode of operation, combined with high precision and repeatability.

Specifically for the design and material selection of the rotor-stator combination, there are several possibilities to perfectly match the dispensing system to the application and TIM. In the case of the rotor, it is possible to manufacture it entirely from ceramic or to provide it with a special multilayer coating to significantly increase the service life.

When it comes to the stator, elastomers, specially adapted for abrasive materials, offer additional optimization possibilities. In combination with appropriate process parameters, the performance and service life of the system can be increased many times over compared to a standard setup. This has been confirmed by numerous laboratory tests as well as in current applications. A technical and commercial comparison with other solutions can also be worthwhile: Due to lower maintenance and setup costs, a quick amortization is possible.

Trends in the field of thermally conductive materials

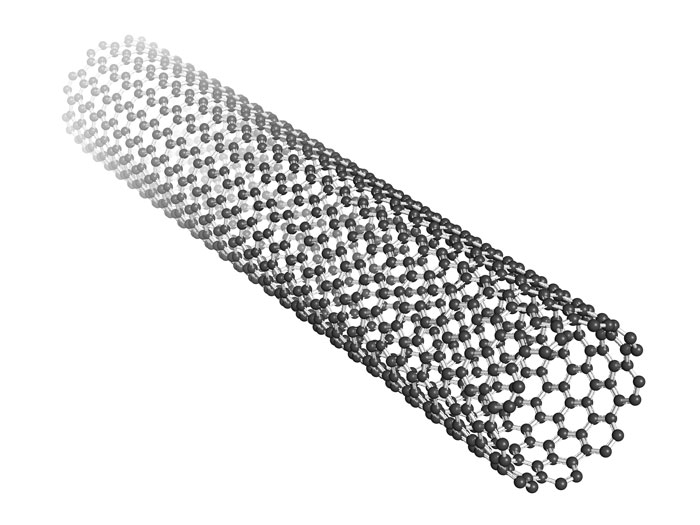

Just as in the development of the equipment for the processing and application of TIMs, the materials themselves are also being continuously developed. In this way, manufacturers are responding to current and future market needs. The driving factors are the increase in thermal conductivity and faster process speeds. These requirements can be met by continuously adapting the filling materials. As in numerous other areas, there is great potential here in the use of plastic nanotubes (Carbon Nanotubes – CNTs). They are characterized by excellent thermal, as well as electrical, conductivity. These properties are further enhanced when CNTs are not arranged randomly but are tightly packed with their longitudinal axis aligned perpendicularly to the substrate surface. The term “Vertically Aligned Carbon Nanotube Array” (VANTA in short) has established itself. Alignment is possible, for example, by applying an external (electric) field. Numerous approaches to this are currently the subject of research worldwide. Whether, to what extent and when CNTs, possibly in the form of VANTAs, will experience their breakthrough in the field of TIMs remains to be seen. If liquid TIMs based on these materials exist, it is necessary to examine what special requirements they place on the production process.

In the case of progressive cavity technology, it has already been possible to adapt the system to the properties of the sometimes highly abrasive heat conducting materials. Should this be necessary in the future for CNT-based TIMs (for whatever reason), the experts on the subject of progressive cavity technology at ViscoTec will search for and find a solution for this, hand in hand, together with external partners in an cross-sectional team.

Summary and outlook

Whether it is in the smartwatch on your wrist, in the electric car in the garage, or from the cell phone provider: TIMs perform their job steadily and unobtrusively everywhere, making our everyday life easier. With continuous further development and adaptation to abrasive material, progressive cavity technology is an ideally suited system for the complete solution of conveying and dispensing tasks with TIMs. ViscoTec offers various solutions for this purpose, from material emptying and treatment systems to dispensers in the microliter range (preeflow® brand). Please feel free to contact us at any time about current challenges, but especially about projects for the “next generation” of TIMs in combination with CNTs or VANTAs.