Plastics: Fillers, anti-friction properties & wear

Materials science offers new opportunities in the dosing technology

1. Abstract

Caused by the high requirements on components subjected to electrical, mechanical or thermal stress in various industries, the combination of diverse properties in the same plastic material is vital. Achieved by the addition of multifunctional fillers, the corresponding procedure is identified as additive applications. The high share of fillers and the corresponding abrasiveness of these additives place huge demands on the processing dosing technology. Against this backdrop the subsequent white paper depicts the need for additives as well as the process impact on the dosing of highly filled polymers.

2. Introduction

There are certainly many approaches to take in order to describe the complex field of plastics, just as there are many varieties of materials.

Nevertheless, if we look back over the past few years, we can see that hardly any new plastics have come on to the market. This may sound bewildering given the enormous growth in almost all areas of the plastics technology. We just accept this claim and admit that the difficulty lies in improving already established plastics. But is this really the case? And if so, which polymers will be added to which additives?

A basic approach would be to look at materials science and its terms and definitions. “Staudinger” defined the term “macromolecule”, which ultimately leads to the definition of a polymer. But a polymer is not a plastic. The macromolecular structure of a polymer primarily determines the physical, and in particular the chemical, properties of the material. This fact limits the areas of application for each group of polymeric material.

3. Need for additives

Two questions have been asked with regard to the limitation: Could it be possible to establish many material groups? And what scope is there for expanding the areas of application within a material group? The answer to both questions is: additives.

The proportion of functionalized plastics being used in components is increasing. It is not relevant whether these are thermoplastics, thermosets or elastomers. In order to produce products with specific properties, the materials used need to be modified, for example, improving the thermal or electrical conductivity, UV protection or impact resistance. The options for modification are diverse and hardly straightforward. In the end, the objective is to optimize polymers through the right combination of additives and fillers in association with the production technology used.

4. Additives and fillers

Plastics are composite materials, which alongside the polymer itself, contain different additives. Basically, two criteria are given in the selection of additives. The first of these is the means of processing. These additives are primarily necessary for the ease of processing in the production process. This group includes, for example, internal and external separating agents, nucleating agents or flow improvers.

The second criterion is the group of additives which improve the property of the plastic and thus the quality of the finished component. Such additives include pigment concentrates, UV absorbers, impact resistance improvers or long-term stabilizers (antioxidants) to name but a few.

This distinction in means of processing and improving the properties only describes the influence of the property characteristics of the material. So, we go further and differentiate between inorganic and organic-based additives. In this way we can differentiate between and arrange the additives used very well. Now we go even further and break down and differentiate between additives and fillers. Fillers are, in the first instance, materials whose function is aimed at reducing the polymer proportions. Additives, however, cause a specific change to the properties of the polymer. Ultimately, the bi-functional additives broaden the polymers change of properties through multiple functions.

Additives are usually available in small quantities. The resulting improvements in the properties are significant in comparison. Therefore, the additive content of plastics must be very precisely defined and observed. Also, correlative influences in fluctuating additive proportions of several additives can affect the desired characteristics of the property.

5. Processing and manufacturing

The desired additives influence both production parameters and the technical characteristics of the plastic. Unfortunately, many of these additives or additional “ingredients” generate problems in the manufacturing process. Problems generally arise in the areas of machine and plant construction and process engineering.

Let us consider glass for example. We can use glass in various forms and with diverse properties as an additive or as a filler in polymers. Fibre glass can be used in different lengths, from micro-short fibres to long fibres or woven fibres. In the processing of thermoplastics, fibre glass has a considerable effect on the abrasion of machinery parts, moulds and tools. This same material, in the form of micro beads of glass, shows much lower abrasion behaviour. In contrast, there is an extreme increase in the flow path to be obtained, although the correlating pressure levels drop. These opposite property characteristics are based on the surface morphology and the pure geometry of the body of glass. The sharp-edged fibre glass is highly abrasive and produces high friction coefficients. These high friction coefficients in turn results in a high viscosity of the plastic mass. This applies to both potting compounds, as well as to thermoplastics. Micro beads of glass have a rolling characteristic, which decrease the friction coefficients and reduce the viscosity.

6. Additives as property enhancement

With the above mentioned influencing factors of the morphology emerges a constant increase in the proportion of the additive. The focus is no longer on achieving a significant change in property characteristics with a reduced proportion of additives. Rather, fillers and additives become the transmitters of the characteristics.

Here we briefly highlight a few materials. Firstly, there are solder pastes, lead-based metal alloys, tin, zinc, copper and silver, with the addition of fluxes for 1 and 2 component systems. Here additives can be added over 90%. Similarly high additive applications can found in thermal pastes, which are mostly oxide and ceramic-based.

7. Plant construction and process engineering

These materials per se are extremely abrasive. With the enormous filler proportion demanded, further high standards are expected in mechanical engineering and process engineering. Particularly in the development of abrasion resistance, materials for machine and plant engineering have to be constantly improved and optimized. As a system provider, ViscoTec Pumpen- u. Dosiertechnik has been meeting these technological challenges for several years with its wide range of applications in the dosing technology field. The constantly changing formulations and innovations in media, combined with the rising demand for chemicals, require continual research. In particular, the combination of rotor / stator is at the heart of the system. The high demand for precision, quality and reliability can only be achieved and implemented in tailor-made materials. In order to offer such a “customized solution”, extensive R&D testing scenarios are required. ViscoTec offers comprehensive testing facilities with regard to chemical and abrasion resistance.

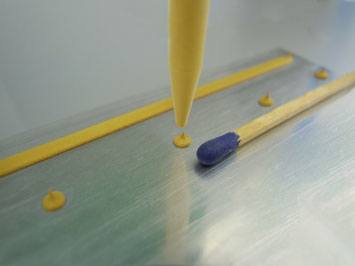

For ViscoTec, the perfect dosage starts with materials science. Static and dynamic test runs of the actual application product are conducted on test stands specially developed in-house.