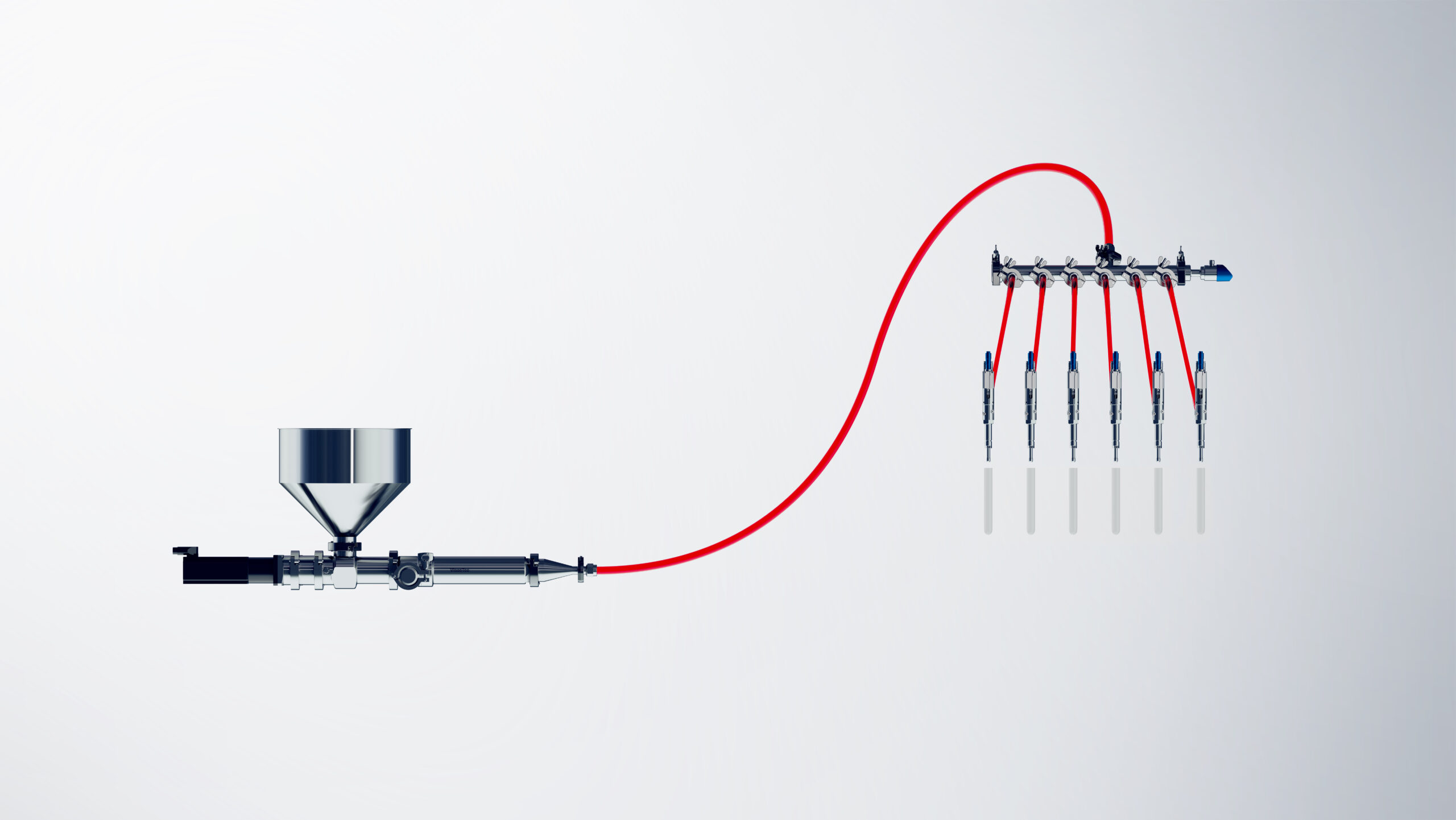

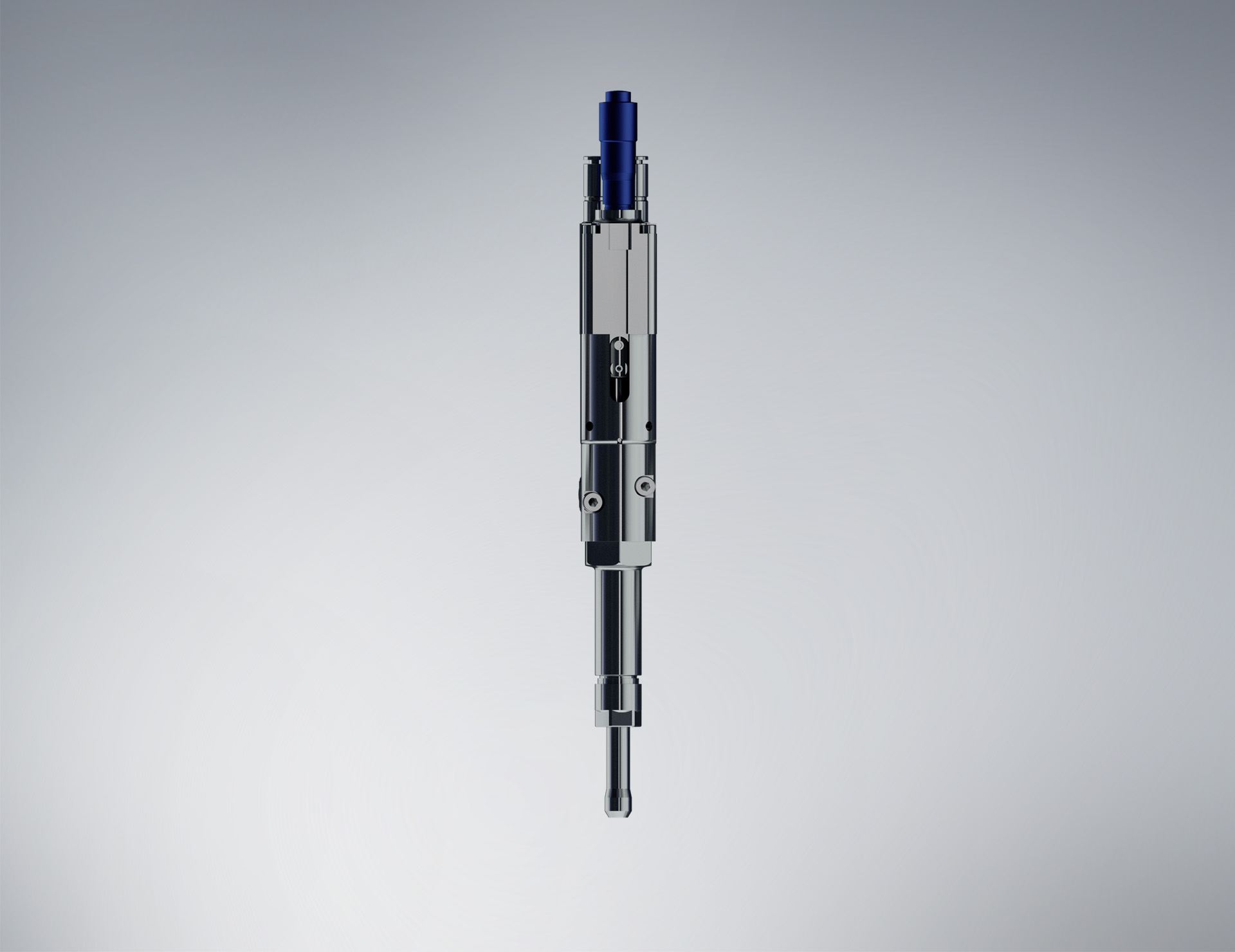

In line with this year’s top themes at Achema, the world’s leading trade fair for the process industry, the innovation driver ViscoTec will be presenting a new product at stand A74 in hall 3.0: The new filling valves, which can be offered and integrated as a complete dosing system, from feeding to filling, customized to the respective application. As usual, they meet the highest standards of hygienic design and achieve drip-free dosing results. Food marinades, cosmetic creams or dishwasher tabs can be precisely filled or dispensed even in confined spaces.

You can see this and much more in this video.

Flexibility in the filling process is constantly increasing due to decreasing batch sizes and the trend towards personalized medicine. This requires systems that can guarantee fast and cost-effective format changeovers.

ViscoTec will also be presenting the solution for this to packaging machine manufacturers at Achema: the vipura-PUMP 10T from the vipura series. To date, it offers the widest range of different possible volumes with consistent accuracy and dosing time, as well as quick and easy cleanability via external CIP systems.

“We have been dealing with the trend towards the largest possible variants for filling quantities, packaging sizes, shapes and different media with their viscosities for a long time,” reports Sebastian Gerauer, Head of Business Unit Hygienic Solutions at ViscoTec. “Efficient production means that the system has to run and not be blocked by frequent component changes or complex cleaning cycles.”

However, the biggest challenge in the filling process is to process the sometimes sensitive media gently and reliably, especially with pasty and solids-laden products. For this purpose, ViscoTec uses the VHD and vipura series, which work according to the endless piston principle. The chambers, which are closed off from each other and have a constant volume, are moved continuously from the suction side to the pressure side with virtually no shear stress. These two dosing systems cover a range from 0.1 to over 500 ml filling volume. This is achieved with dosing times of less than one second and a dosing accuracy of > 99% at the pump outlet.

In addition to dispensers, ViscoTec offers complete product handling for dosing and filling applications. Feeding and preparation systems and the associated control technology ensure the supply of the dispensers and guarantee a validatable process.

Experts for the respective applications will be available at the stand to support you from the initial idea to the final implementation of the project. ViscoTec also offers customer-specific tests in the laboratories of the Customer Innovation Center. The laboratories are tailored to the needs of the respective industry or application. This means that complex and long-term tests as well as very individual customer requirements can be verified.