ViscoTec Dispenser Technology: Innovative precision dispensers for industrial applications

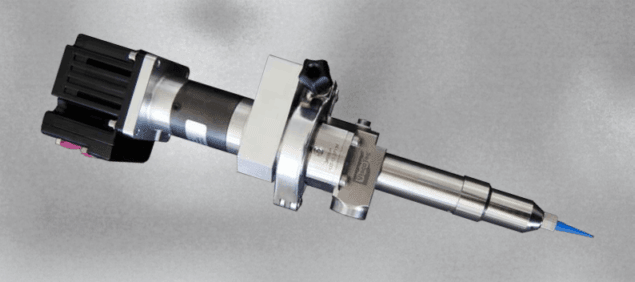

ViscoTec dispensers of the RD series..

characterize dosing systems with a constant volumetric operating principle for an uninterrupted and highly precise dosing process by using of the endless piston technology.

The dispensers guarantee a precise, consistent and reliable dosing performance for a wide range of liquids and compliance with the specified dosing precision even with varying media densities and viscosities.

Special rotor-stator geometries…

allow flexible control of the amount of the liquid conveyed and the direction of the medium flow. Alternately opening chambers provide for a gentle transport of the medium inside the dispenser and a pulsation-free output. Each individual dispenser chamber conveys an exactly defined volume of medium and works simultaneously as sealing line in the way of the pump inlet and outlet side.

Valveless dosing technology

The valveless system design is based on a circumferential sealing line in order to prevent leakage of the medium at the dispenser outlet side. In addition, the ViscoTec RD-dispensers provide a programmable suck-back option at the end of each dosing step.

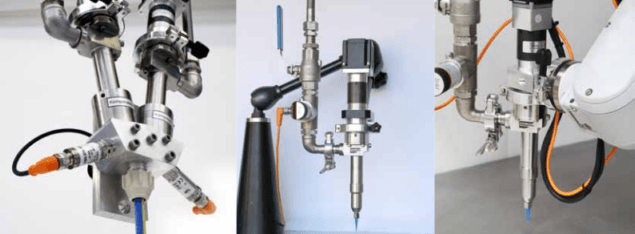

System integration/precision

Dosing quantities in the range from a few μl up to larger ml volumes can be dosed with maximum precision as a dot, bead line application or within potting processes. The dispensers can be integrated into a wide range of axis and robot systems due to their compact and weight-reduced structure.

Along with the combined ViscoPro drive and control systems the dispensers can be integrated as overall dosing systems into production lines.

Dosing systems

Beside its use for dispenser technologies the endless piston principle from ViscoTec is also selected for the material emptying and material treatment systems. In this way ViscoTec can assure a consistent and high quality processing of materials throughout the entire dispensing procedure from material supply up to the dosing process.

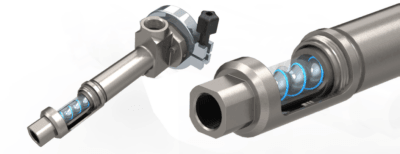

RD-EC (Easy Clean) dispenser platform

With the current generation of RD-EC (Easy Clean) dispensers cleaning and maintenance costs are specifically reduced to a minimum and a high level of system availability is assured in the industrial production processes. The housing shape of the EC dispenser allows an easy and comprehensive access to the inner pump area – especially to the rotor and drive shaft – even without disassembly of the sealing housing. In addition, the costs for cleaning materials and their disposal can be reduced significantly. As a consequence, production at smaller batch sizes can be realized economically and lines resources operated on higher utilization rates.

Divisible housing

The introduced system benefits of the ViscoTec EC dispensers in terms of system cleaning and system maintenance are achieved by a separation of the dispenser housing into a sealing housing section and a separate pump housing unit.

The sealing package is completely integrated into the separate bearing/sealing housing, so that the sealing package must not be dismantled any longer during the cleaning process (e.g. during product change or regular maintenance).

Product benefits

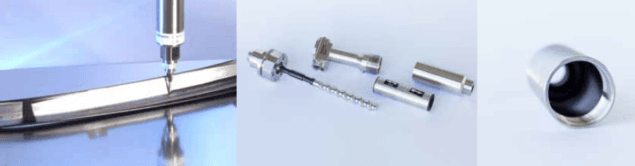

- easy assembly/dismantling of the dispenser for cleaning procedure

- free access to the entire internal pump space

- reliable inspection and simple cleaning of the internal pump space

- enhanced maintainability at identical high dosing accuracy

- possibility of on-site verification of dispenser conditions

- verification of the sealing unit during the cleaning service

Advantages for an efficient production process

The enhanced product features of ViscoTec RD-EC dispensers help to optimize industrial production processes:

- increased system availability due to an efficient cleaning process

- reduction of overall maintenance costs

- optimized cleaning procedure enables processing also of more critical materials

- simple upgrade of existing production lines to the new ViscoTec EC-technology by minimized system downtimes

Control concept

The engine speed of the dispenser drive units is controlled by an analogue signal directly connected to the motor interface. The dosing volume is provided with high accuracy and in direct linearity to the analog signal level at the dispenser output. The additionally available suck-back function offers the process-related option to actively prevent material dripping effects at the end of the dosing cycle and to control the cut-off string of a medium through program settings.

2-component-applications can be configured and controlled by an additional, dedicated dispenser control system, which synchronizes 2 individual dispensers units by a 2-component master routine. The dosing parameters for a 2-component application, such as the mixing ratio and the total volume to be dosed, are set via the recipe management interface and automatically converted into individual control commands per dispenser by the 2-component controller.

Innovative dosing technology

With every pump rotor rotation of the precise volumetric operating RD-dosing technology a defined, highly repeatable volume of medium is applied. With each rotation of the rotor per time slot a corresponding dosing volume in ml is applied per identical time slot. The ViscoTec principle provides a linear correlation between the dispenser rotation speed and the dosing quantity; a change in the rotation speed leads to an equivalent change of the dosing volume without any delay. This accuracy in dosing volumes is achieved with high reliability and pulsation-free even with fluctuating liquid viscosities.

Precise dosing of highly viscous and filled media

ViscoTec RD-EC dispensers reliably process media with viscosities of up to 7,000.000 mPas (cps). The dosing principle enables a low-shear transport of the medium and is suited especially for dosing shear-sensitive, filled and abrasive materials with constant high process accuracies. Available is a wide range of stator materials with chemically and mechanically highly resistant elastomers across all pump sizes. The dosing pumps can cover a wide range of specific process requirements for various type of media.

Applications

The dosing systems can be configured and used for multiple applications within a wide spectrum of media. Systems are available for processing of adhesives and sealants for both – 1-component applications as well as 2-component applications with the possibility of programmable settings of the mixing ratio:

- Dosing, application, potting, 2-component processing and volumetric spraying technologies of 1-component and 2-component adhesives, sealants, pastes and potting materials

- Application of dots and beads, possibility of programmable setting of dosing quantities and flow rate as well as mixing ratios for 2-component applications