Clean and product-friendly filled into dispensing syringes

High viscous products such as ointments, creams and gels often do not naturally flow. For this reason, they are dispensed into tubes or jars for application. But dosing syringes are used for the precise application of highly effective substances. By pressing down on the plunger, the user can dose the product more accurately and easily and apply it more cleanly. As is the trend with highly effective substances, the quantities to be dosed are getting smaller and smaller and therefore the accurate filling of the dispensing syringe is all the more important. Conventional filling technologies used in the pharmaceutical industry are reaching their limits when it comes to the highly accurate filling of viscous or paste-like products into syringes.

In order to find a suitable new filling technology, DendroPharm GmbH, a spin-off company of the Free University of Berlin, carried out clinical trials for the filling of high viscous thixotropic ointment. DendroPharm, which was established in 2013, has developed nanocarrier systems based on dendritic biodegradable polyglycerols. These amphiphilic carrier systems enhance the penetration of both lipophilic and hydrophilic active agents into the skin or into tumor tissue. The company offers customized nanocarriers syntheses, the development of pharmaceutical formulations and joint projects to develop new medicines, including support services for administration and project management.

For the above-mentioned trials, 10,000 dispensing syringes must meet GMP standards when filled: with 1ml water-less ointment (with an approximate dynamic viscosity of 160,000 mPas) free from air bubbles and with a tolerance of +/- 1%. It is a multi-dose dispensing syringe. A single dose is less than 5µl. By using the syringe, the user can dispense and apply the ointment very well. Since existing systems cannot be used for syringe filling due to their low accuracy, it was decided to purchase a GMP-compliant filling station.

The ointment is currently being produced in 20kg batches. It is important to work with minimal product wastage. The filling process should be carried out semi-automatically and as user-friendly and reliably as possible. The technology used must be validated by the Pharma industry, meet appropriate cleaning requirements and use FDA compliant materials. Until now the GMP compliant filling has been carried out externally, however, it is planned to do this in-house. The system must therefore be mobile.

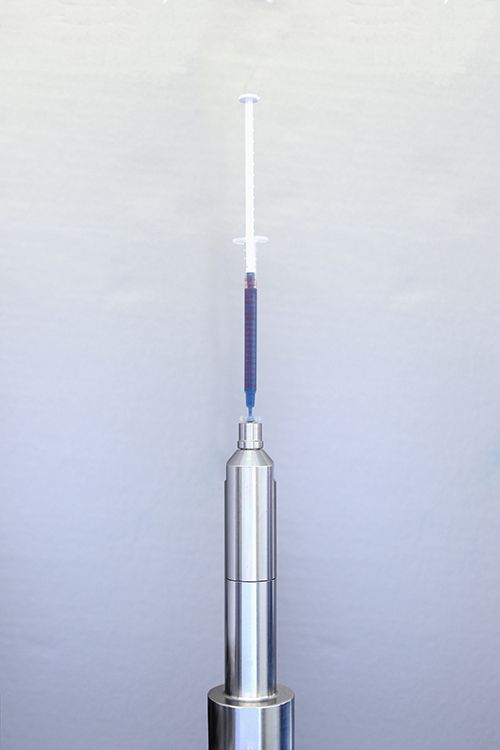

With its Pharma dispenser, Viscotec offers the optimal solution for the filling of syringes. The ointment is fed into the dispenser using a pressurized cartridge. The syringe is attached to the pump outlet using an adapter. The filling process is started by the operator pressing the start button on the HMI panel or alternatively by means of a foot switch. Once the filling process is complete, the operator removes the syringe and closes it with a cap.

The syringe is filled through a cone which allows for bubble-free filling. High pressure can form due to the viscosity of the medium and the small opening, however, this can be managed by using endless piston technology. A small amount of the medium is withdrawn from the cone at the end of filling in order to keep it clean. For this part of the filling process, the direction of the rotation is changed so that the ointment can be accurately retracted back into the filling needle. This retraction function can also be applied to media whose threads do not break easily. Volume, velocity and acceleration can be individually adjusted depending on the requirements of the product. As a result of the defined breakage of the threads, a very good and extremely precise filling process is carried out.

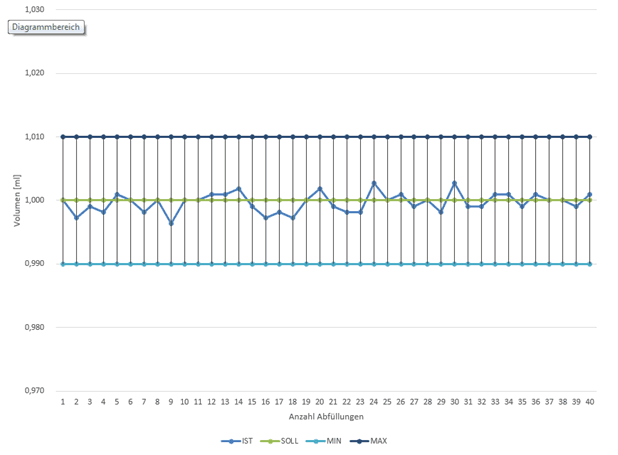

Trials to determine the filling ability and optimal filling parameters of the ointment were jointly carried out at ViscoTec’s testing plant. These filling trials achieved a filling tolerance of under +/-0,5%, as well as a very good repeat accuracy. For the 40 fillings, the dosing of 1 ml fell within a range of 0,996ml to 1,004ml, with a probability of 99,7% (3 times standard deviation).

The Pharma Dispenser will be installed at DendroPharm. Due to the manageable size of the system, it can be stored in a cupboard until it is required. It is therefore an extremely space-saving system. In setting up the filling system all that is required is a 230V connection for the controls, as well as a compressed air connection with pressure regulator for the cartridge and a holder for the dispenser. Thanks to the modularity of the system, it can be easily adapted with little effort for the respective application. DendroPharm is supported by dispensing specialists from ViscoTec and extensive commissioning documentation.

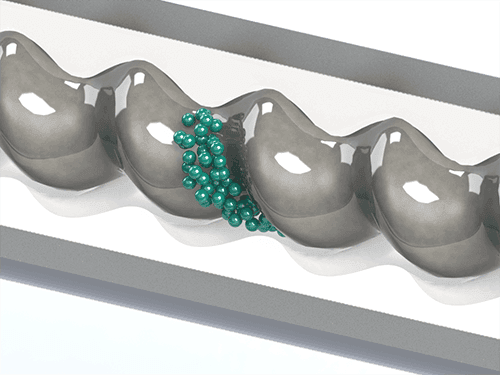

Like all ViscoTec dosing pumps, the Pharma Dispenser is based upon endless piston technology. This technology includes rotating positive displacement pumps and thereby eccentric screw technology. The stainless steel rotor moves eccentrically in a stator made from elastomer. Through the interaction of rotor and stator, chambers are formed. The size of these alternately opening chambers remains constant during the rotation, so there is no compression of the product. This geometry allows for a precise, gentle and pulsation-free product flow.

In addition to liquid media, high viscous creams, gels or pastes (< 500.000 mPas) can also be supported for perfect pulsation-free filling. Even abrasive products can be filled. This shear-sensitive technology is also well suited for biotechnological products, products with solids such as suspensions or medicines containing crystals.

Conclusion: The Pharma Dispenser is the ideal solution for the precise, semi-automatic filling of semi-solid pharmaceutical products and can be used for production in campaigns at any time. It excels in providing a clean, gentle and highly precise dosing of any substance from liquids to high viscous media.