Service

Commissioning / After Sales Service

We accompany you for a (pump) lifetime

Customized equipment & processes

Our goal: To improve your processes

Going beyond what we have to is also our principle when it comes to service.

Our services therefore extend well beyond standard service.

Our service experts are happy to be your first point of contact for the following topics:

Quality assurance

Let’s face it: Making quality visible at all levels is almost impossible when it comes to complex technologies. To ensure that we always supply you with the best possible quality, we pay meticulous attention to the quality of the raw materials as early as the goods purchasing stage – for us, “Made in Germany” starts right here.

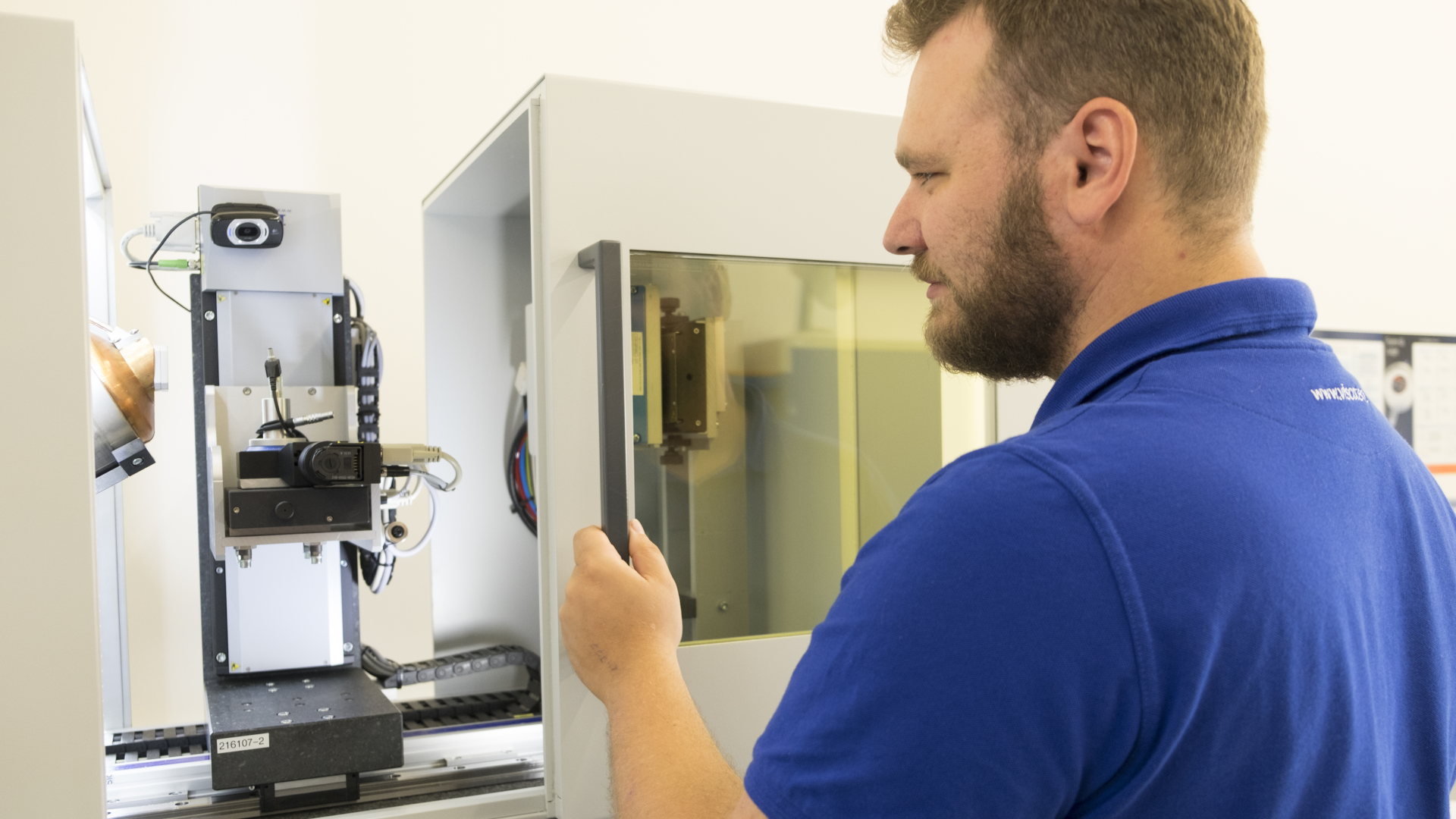

And we also go our own way when it comes to the goods we deliver: Our claim is no less than to develop the most high-precision dispensing technology. Among other things, this is made possible by a computer tomograph (CT). With this device, which is familiar from medical technology, we measure the inside of dispensing systems non-destructively and precisely to the hundredth of a millimeter and therefore evaluate the quality – even of very small systems. Hundreds of images then depict the three-dimensional geometry of your component and, with an eye to quality, reveal all details for a clean production check. Another plus: Each of our systems is tested for functionality in terms of control technology and mechanics – always.

CT proves to be a non-contact, enormously efficient and reliable measuring method, which we also use in the following fields of activity:

- Development

- Failure analysis

- Quality assurance of electronic components

Would you like a CT of your components? Contact us – our experts will be happy to assist you – with or without CT.

After Sales Service

We are not satisfied until you are. And since our technology is known for its long service life, we are at your side from delivery to your company, through installation and commissioning, and throughout the entire product life.

This already starts with commissioning and manifests itself in the following details:

- Simple support of your colleagues during commissioning

- Competent instruction of your operating personnel

- Efficient recommissioning after storage and reassembly

- Technical support during plant integration or plant modification

Competent support during operation

Once the system is running, we are there for you with our competent support during operation and help with possible faults – quickly and without complications. Our spare parts supply is similar! And the fact that we are also your first point of contact for intelligent maintenance concepts and process optimization also speaks for us and therefore also for you as the manufacturer.

So that we can guarantee you our help at any time, we have established a central contact point for all technical service questions. You can reach us from Monday to Thursday between 8 a.m. and 5 p.m. and on Friday until 12 p.m. by phone at +49(0) 8631 9274-115 or for appointment and service requests via mail to service.support@viscotec.de.

To help you get to know us a little better without the personal contact, Fabian Schirmer, Head of the Service Department, briefly introduces his team:

Keyword Core Competencies

All service technicians have mechanical or electrical training. Several years of professional experience – also in assembly and disassembly – make our colleagues ideal contacts for your service questions. In addition, each employee has become acquainted with all production departments and is only allowed to install a system completely by himself after almost one year. For us, service is also always teamwork: Everyone has their role, on site with the customer or in the back office. All in all, this results in top performance, satisfied service staff and a great increase in customer satisfaction.

Keyword Service

With us, everything revolves around a quality-oriented approach. Our 2nd level employees are selected service technicians who answer your support requests quickly and straightforward, thanks to technical expertise. If you require even more specific know-how, technical specialists from various areas (e.g. machine programming) are also available to assist you at 3rd level.

Our excellent support is only possible with motivated, well-trained and flexible employees. As a company, we do a great deal to ensure this motivation: We provide material and financial resources that are needed for service immediately. We also offer company cars, the necessary IT equipment and further training. A healthy work-life balance is more a matter of course than a novelty for us.

Keyword Service Hotline

We like to give a little more, which is why you can contact us free of charge even beyond the legal warranty. Whether it is a service request, maintenance, IBN, repair or process optimization, the important thing is that you get your answers, and our customers are satisfied.

Keyword Future and Support

We are constantly working on becoming even better. That is why we are currently planning the introduction of new workflows and the use of software, dedicated specifically to the service area. The service is also to be clustered into further modules in order to quickly find the best contact person for your topic.

Process optimization / process development

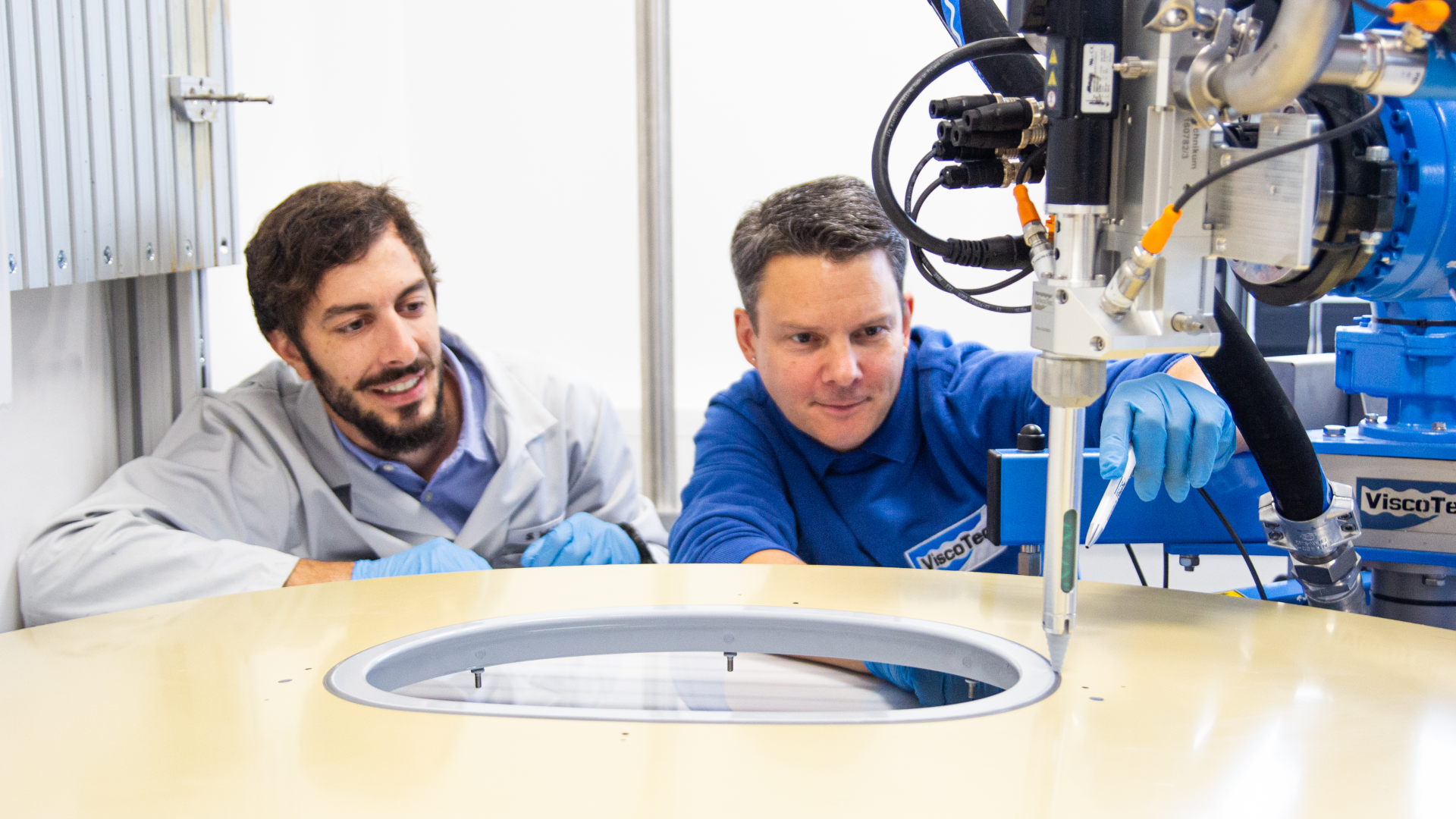

Is the handling of fluids also high on the agenda in your company? And do you notice in your daily work that processes could be significantly improved? Then you have come to the right place – regardless of whether you handle fluids manually or rely on partial or full automation. With us, you have found a strong service provider who is dedicated to all your challenges. If you have already established a process, we will analyze it in detail. Either in real time at your site or in our technical center, under laboratory conditions that replicate your process.

Our goal: To guarantee maximum efficiency and safety as well as to maintain and, at best, even increase product quality.

If you are also looking for a dispensing solution with contemporary standards that meets your needs both process-wise and economically, we should get to know one another.

Customer & Innovation Center

Speaking of laboratory and pilot plant: You can test and analyze your material to be conveyed in our pilot plant at any time. You can reach the CIC easily via the A94. And from Munich Airport you can reach us within one hour by car.

With various handling systems (2 Kuka robots and a variety of axis systems), we can realistically simulate your automated process. And we will also be glad to work with you to select the right dispensing equipment for your process. To help you make the best decision, we are glad to make our five laboratories in our CIC available to you. One of them is specially designed for Hygienic Solutions and, if necessary, a robot cell is also available for you here. There is also a room for industrial systems, a UV pilot plant, and one for microdispensing/preeflow.

Optionally, we will gladly provide you with a test report. Part of this detailed documentation are all parameters, photos and of course a presentation of the results.

If you want to know more about viscosity, our viscosity calculator will give you the first answers immediately:

Viscosity Calculator

Viscosity is the measure of the liquidity of a fluid or paste. The higher the viscosity, the more viscous or pasty and therefore less flowable the material. The individual molecules of highly viscous fluids are strongly bound together and therefore more immobile. The lower the viscosity of a material, the thinner it is. The term viscosity comes from the viscous, sticky juice of the berries of mistletoe (viscum). In Roman times bird glue was made from mistletoe: Bird catchers used it to coat their rods. “Viscos” essentially means “as tough as bird glue”.

The effect of internal friction is imagined in simplified terms as the movement of two interlocked molecular layers lying one above the other. During flow, the molecules slide past each other, and a certain force is required to overcome the interlocking. This force and the properties of the material in question define its viscosity. Here is the calculator:

>> To the viscosity calculator

Technical Background:

Low- to high-viscosity and pasty material can be optimally dispensed by progressive cavity pumps. A uniform volume flow – generated by the endless piston principle – prevents sedimentation of the fillers at different densities. The low pressures of up to 40 bar, and the specially developed rotor-stator geometry, ensure wear reduction through extremely low-shear conveying, little to no pulsation and no backflow in the individual chambers. All material, which in individual cases have a viscosity of up to 7,000,000 mPas, are conveyed and dispensed with volumetric dispensing systems such as those from ViscoTec, with virtually no pulsation and extremely low shear.

Our internal technical center proves that we not only have your satisfaction in mind, but also never tire of testing and improving ourselves. This is where our experts work on equipment and processes. Quite successfully: Last year, we carried out almost 200 tests – our own and those for our customers. If you are considering a rental system instead of, or in addition to tests, please contact us.

Why do we do all this? Because we are good at it. And because we are always looking for the best and most complete solution to a problem. Our customers acknowledge this: They have trusted us for many years. Maybe soon you will too?