Challenges in handling liquids filled with solids

Suspensions are dispersions of solid particles in a liquid. The solids correspond to the dispersed phase and the liquids to the dispersing agent. The production of suspensions enables the conversion of sparingly soluble active substances into a liquid pharmaceutical form. Therefore, suspensions are used in various pharmaceutical applications – both internally and on the skin. Examples of applications are suspensions of acid-binding inorganic active substances and antibiotic juices. As undissolved substances are not perceived in terms of taste, unpleasant tasting active substances can also be administered orally. This plays an important role especially in paediatrics.

In many cases, the particles of a pharmaceutical suspension have a diameter of 100 µm and more. Thus, as a rule, these are coarsely dispersed systems. Depending on the application, the solids content of a suspension is between 0.5 and 50 %.

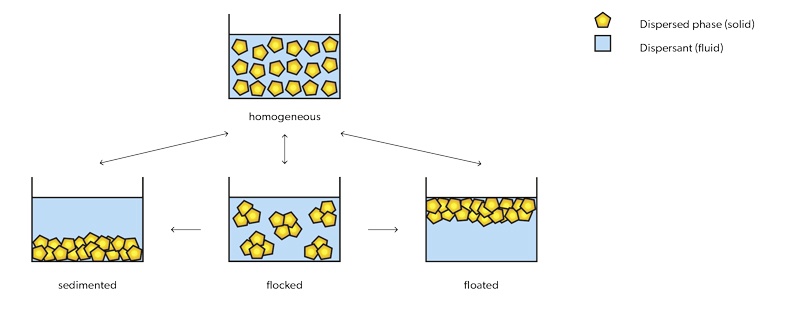

The interfacial energy stored in the system and the difference in density between the dispersed phase and the dispersant can cause instability. Pharmaceutical applications with suspensions, however, require a homogeneous product, since a uniform solids content must be ensured.

The disadvantage of suspensions is the tendency to sedimentation during prolonged storage. In practice, however, it is difficult to restrict or avoid such properties. Stabilizers can be used to avoid or at least slow down the instability problem and sedimentation, flotation or flocculation. These increase the viscosity of the preparation. In the pharmaceutical industry there are various mucilages that are used to increase the viscosity. These include tragant, pectin, methyl cellulose, hydroxyethyl cellulose, carmellose sodium, hydroxyalkylated starch derivatives, sodium alginate, acrylic acid polymers and dextranes. The type and dose of the stabilizer is determined empirically for each individual case. In general, sedimentation is permitted in pharmaceutical suspensions. However, the prerequisite for dosing is easy shaking in order to completely redisperse the sediment. Pharmaceutical manufacturers are therefore faced with the challenge of filling suspensions independently of viscosity, gently to the product, homogeneously and with a high degree of accuracy. It should also be possible to dose abrasive fillers.

ViscoTec – specialized in moving, processing and dosing of viscous, structure-sensitive and solids-laden liquids – offers precise solutions. Due to the abrasive or shear-sensitive properties of the fillers, pump types such as peristaltic or rotary lobe pumps are only conditionally suitable for dosing suspensions. The ViscoTec dosing units have proven themselves in this field. As progressive cavity pumps, they are among the rotating positive displacement pumps. The stainless-steel rotor moves eccentrically in an elastomer stator. The interaction of rotor and stator creates chambers. The size of the alternating opening chambers is also constant during rotation, so that no compression of the conveyed product occurs. Due to this dosing geometry, a constant volume is always conveyed in proportion to the angle of rotation per revolution – independent of the viscosity of the medium and with pulsation-free product flow.

This fact guarantees a dosing accuracy at the pump outlet of 99 % (depending on the medium), which is often exceeded in practice. Compression-free conveying also allows highly viscous and shear-sensitive media to be conveyed or filled. The pump technology of the endless piston principle has additional advantages over other dosing mechanisms. For example, filling and metering valves can be completely dispensed with in over 95% of all applications. Retraction (reversal of the direction of rotation of the dispenser) results in controlled yarn breakage and prevents dripping. This advantage allows, among other things, the exact dosage of suture pulling gels or resins.

Another advantage over hose and piston pumps is the possibility of integrating a bypass into the pump. In this bypass, the material can be kept in motion during the dosing process and at a standstill of the system. In critical applications, this prevents sedimentation in the pump feed. The volume flow shown in the figure also offers the possibility of venting the pump.

A typical application of suspensions is the dosing of pharmaceutical products in blister forms. The products of ViscoTec are already successfully used for this purpose in various production plants. In a specific application, sedimentation could be reduced by using ViscoTec metering technology and the longevity of the metering pump could be improved. The metering pumps used here meet the requirements of GMP and FDA guidelines. This means that we also pay due attention to cleaning and documentation. After use, the dispenser can be dismantled in less than one minute without tools and can be cleaned in cleaning baths or in automated rinsers and sterilised in an autoclave.

Further information about dosing and filling of high viscosity pharmaceuticals you can find here.