Endless Piston Principle

Functionality and benefits

At the heart of every application is a volumetric dosing system. The interaction of a rotor with eccentric motion and a stator adapted to the conditions of the application results in conveying and dosing characteristics which correspond to an endless-motion piston.

Due to the dosing geometry, a constant volume is always conveyed proportionally to the angle of rotation per revolution. The conveying direction can be reversed by changing the direction of rotation. The volume is therefore unambiguously defined via the angular degrees.

Our technology provides a pressure-stable, linear head capacity curve of the pump. This enables a clear statement to be made regarding the ratio of revolution, time and discharge rate. So the pumps can be used in an application to dose a constant volume based on either time or revolutions. This fact results in a reliable dosing precision at the pump outlet of 1% (depending on the medium), which is often undercut in practice.

Another benefit is the conveying chamber produced, whose volume remains absolutely constant throughout the motion. As a result of this, solids-based media and even lumpy products can be conveyed and delivered.

Our pump technology provides additional benefits compared to other conveying mechanisms. For example, in over 95% of all applications there is no need for any filling and dosage valves at all, since a short reverse motion at the end of the dosing process causes threads to be broken off or prevents dripping.

Industrial requirements to the technology

Particularly in industrial sectors with extremely complex requirements and sensitive systems, optimum adaptations, long service life and professional service are the basic prerequisites for secure production. What does an application system have to contain if it must accommodate the dosing and application of high-viscous, abrasive and shear-sensitive adhesives or sealants whilst tolerating changes in the flow characteristics of the media at the same time? Furthermore it must be easily adaptable to networked control systems.

With the proven endless piston principle our dosing systems work free of pulsation and in a way that is particularly gentle on the product. Our dispensers are characterized by a high degree of repeat accuracy and extremly precise dosings through the smallest dead spaces.

No dripping thanks to adjustable suckback, no accumulation of product at joints, uniform caterpillar form even at a different traversing speed, dot dosing and bead dosing using one device and an infinitely adjustable dosing quantity are just some of the benefits offered by our technology.

Precise dispensing due to the endless piston principle

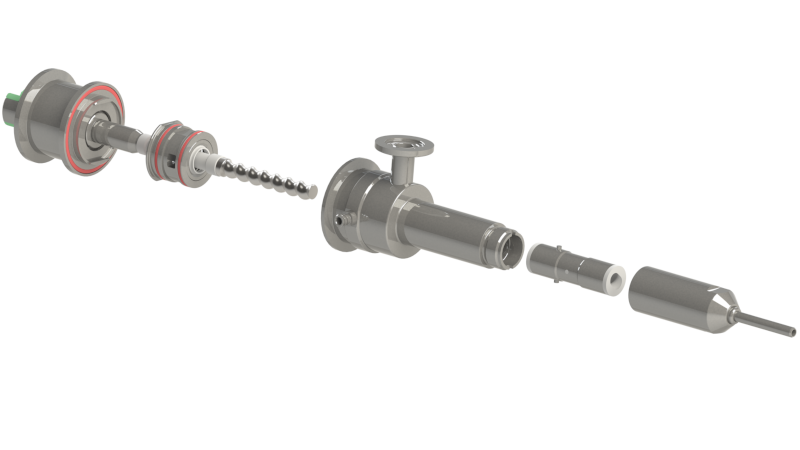

ViscoTec dispenser are based on a completely pressure-tight displacement system, which is self-sealing and consists of a rotor and stator. The controlled rotary motion of the rotor causes the medium to be displaced in the stator and generates the conveying movement.

Since conveying can also take place in reverse, ViscoTec ensures that the material or medium is broken off cleanly and in a controlled manner without dripping. Our micro-dispensers enable micro doses from 1 µl to be administered with a high degree of process security and a dosing precision of ± 1%, plus a repeat accuracy > 99%.