3D Printing

Fluids & paste printing with 3D print heads based on endless piston principle

The vipro-HEAD series is available in different versions. For 3D printing of one-component and two-component materials. And with the proven accuracy and precision of ViscoTec products – thanks to our endless piston principle.

Our 3D printing process is very similar to the filament printing process (FLM). Therefore, the vipro-HEAD also works with all common slicer programs and printer firmwares. The print head conveys purely volumetrically from the dispensing needle – and produces a three-dimensional structure line by line. It is controlled directly by the 3D printer (stepper motor signals). Fast and easy integration into additive manufacturing machines is guaranteed. You can also find more info in our brochure.

The advantages for you at a glance:

- Volumetric dosing

- Reversal of the conveying direction possible („Retract“)

- Clean and precise start and end points

- Dosing regardless of viscosity

- Very wide range of printable materials

Application examples 3D printing

Textile printing with silicone

3D printing has been part of the textile sector for some time now. But the materials used have weaknesses. They normally don’t offer enough flexibility and elasticity to adapt to the characteristics of fabric.

That’s why Lynxter started tests with printing silicone on fabrics. Silicone is very soft and elastic and adheres very well to fabrics. In addition, it offers excellent resistance to chemicals and UV rays. Lynxter used a printer in which a vipro-HEAD 3 is installed. Click here to read the detailed report.

The video about textile printing:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

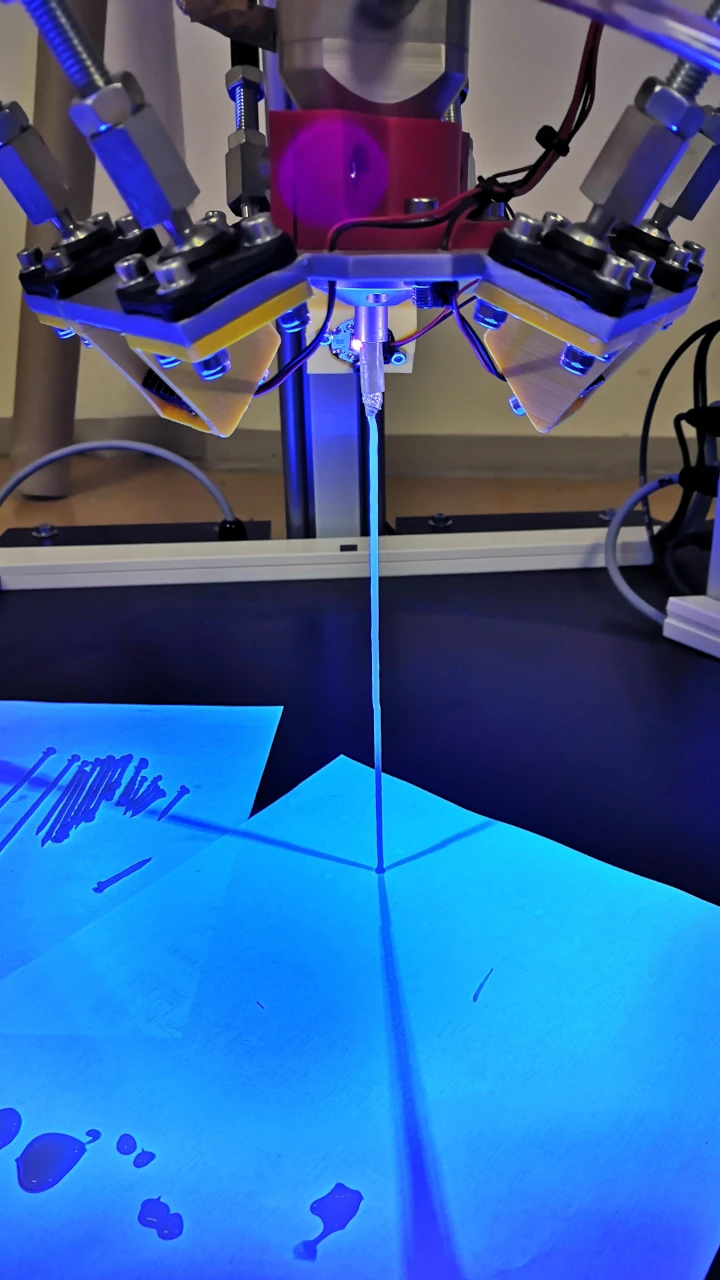

More Information3D printing in space

Is 3D printing also feasible in weightlessness? This question was investigated by the AIMIS-FYT team at Munich University of Applied Sciences. As part of their project, they demonstrated a 3D printing process that can be used to produce structures for solar panels, antennas or other installations in space.

Printing in the experiment is done with a vipro-HEAD 5. The AIMIS-FYT team’s experiment uses a photoreactive resin. The resin is extruded and cured by UV light. The full AIMIS story can be found here.

The video about the experiment:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationPneumatic Actuators

In an internal test, very small and filigree pneumatic actuators respectively soft grippers were created in the ViscoTec 3D technical center.

The miniaturized parts were printed with a vipro-HEAD 3/3 and 5/5.

The material used is a two-component silicone. Read here how the vipro-HEAD achieves a whole new level of precision for soft robotics.

The video shows the manufacturing of the flexible gripper:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationOur most successful integrators: